There are two basic steps involved in the repair of a timber member. The first is to remove the reason for deterioration, for example by eradicating beetle attack or preventing the water penetration causing dry rot. The second is to select an appropriate repair technique and among the options available is the replacement of defective or rotted timber with reinforced synthetic mortar. In such cases the overall objective is to restore the original strength and load-bearing properties of a member. For upgrading or providing additional loadcarrying capacity to existing sound timber, bolting, bonding, the insertion of new timber, steel plates, reinforcement bars or laminated beams are amongst the options available. The difference between timber and concrete repairs is that with timber renovation the synthetic resin is not the ultimate criterion in effecting a successful repair. Steel reinforcing bars or plates also play a major role in the total structural system(30).

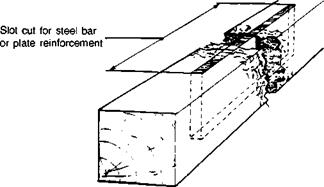

Cracks and shakes in the timber may be initially consolidated by the injection of synthetic resins. This serves to re-establish the member’s ability to support its own weight and provides a suitable base for bonding subsequently applied repair mortars. Epoxy, polyester or acrylic resins can be suitably formulated to provide the fluidity necessary for maximum penetration and impregnation of the wood fibres. Introduction of a solvent just prior to use enables the resin to be soaked up by the timber before chemical hardening occurs. Any decayed timber is then replaced with a resin mortar, the strength and properties of which may be varied to allow subsequent working, for example nailing or sanding. Structural stability is restored by introducing steel reinforcement elements into the damaged area, for example as Fig. 6.22 shows for the rejoining of a rotted mid-section of a beam.

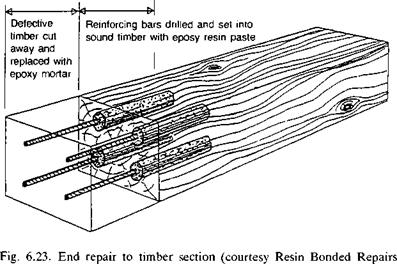

In old buildings timber often fails where it enters a masonry wall or in roofs at the junction of rafter and tie beam where the truss is supported on the wall plate. In both cases leaking water over a long period has resulted in wet rot. The repair process consists of replacing the decayed timber with reinforced epoxy mortar. The reinforcement may consist of steel plate or bars which are drilled or set deep into the sound portion of the timber to ensure a good bond and load transfer. Fig. 6.23 shows bonded dowel bars used to repair the end section of a column or beam while Fig. 6.24 illustrates a typical repair to a roof truss.

|

|

|

Deteriorated or worn timber floors can be upgraded by bonding new timber to old with epoxy resin. The procedure involves removing all deteriorated timber back to a sound surface prior to the application of a penetrating epoxy sealer. The new timber is then bonded to the old and composite action ensured by drilling and inserting dowel pins set in resin as shown in Fig. 6.25.

Fig. 6.25. Upgrading a timber floor (courtesy Resin Bonded Repairs Ltd).

29 августа, 2015

29 августа, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике