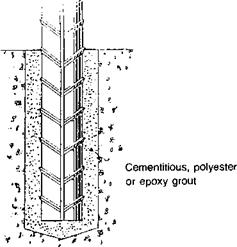

There are two basic methods by which steel bolts and bars may be anchored into concrete, masonry or brickwork utilising epoxy or polyester resin grouts(5). The first involves inserting a deformed bar or bolt into a preformed or drilled hole into which the resin grout has been poured (Fig. 7.3).

|

Fig. 7.3. Fixing using pourable resins (Ref. 5). 247 |

|

Table 7.1. Typical resin quantities for fixings using pourable resins (ml per 100 mm of bonded length)

|

Maximum anchorage strengths and efficiency are achieved in holes drilled with rotary percussive air drills using an air or water flush to remove dust. Diamond drilled holes are not recommended unless the sides are roughened or are under-reamed using special tools. After the holes have been drilled the correct volume of resin should be mixed, according to the manufacturer’s instructions, and poured in. Table 7.1 typifies the information provided by manufacturers of proprietary systems to assist in estimating the quantity of resin to be used. The bar or bolt is then lowered into the hole and pressed gently to the bottom, displacing the resin to grout the annulus around the bolt. A slight agitation of the bolt may assist the grout to settle evenly around the anchorage, especially in cold weather. When the bolt is centred it should be left undisturbed until the resin is set.

The failure mode of grouted bars may be by conical rupture of the base material or slip at the resin/substrate interface. Edge distances and centres must be sufficient to generate the full pullout strength which is related to the bolt type and diameter, the embedment length and the strength of the substrate. The design procedure is to select the bolt or bar diameter according to the load to be carried and the characteristic strength of the deformed portion. The embedment length, L, is then calculated using relationships of the form L = (50 + 25P) mm where P is the load to be carried in tonnes multiplied by an appropriate factor of safety(6). A factor of 2 is normally applied. Potential performance may be affected by:

(1) inadequate cleaning of holes after drilling

(2) low or high temperatures

(3) fire

(4) creep under sustained load

(5) cyclic or vibrating loads.

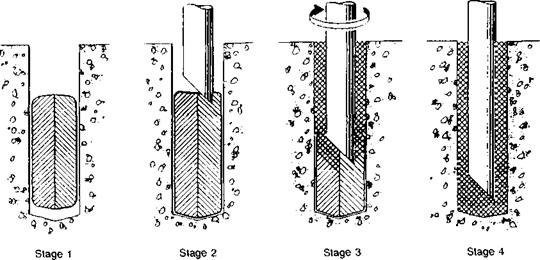

The second type of system is marketed as encapsulated packs of polyester or epoxy resin within which there is a thin skin to keep the two components separated. The capsules are placed in the hole and are fractured when the bolt or bar is inserted and turned (Fig. 7.4). In all such systems it is essential that the fixing is mechanically rotated in the hole to ensure correct mixing of the resin components. The requirements for drilling and cleaning the hole are similar to the poured grout systems but the hole size should be strictly in accordance with the manufacturer’s instructions. This is to ensure that the pre-measured volume of resin in the pack completely fills the annulus between the bolt and the hole.

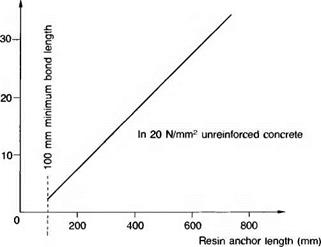

The failure modes and the performance of encapsulated resin fixings are similar to those described for the grouted systems. Manufacturers frequently provide graphs of the form shown in Fig. 7.5 for determining the required anchor length. In using such graphs it is important to ensure that an adequate bolt type and size is first selected, that the graph is applicable to the substrate material and that the load is multiplied by an appropriate factor of safety prior to use.

The concept of encapsulated packets of resin has proved most popular for polyester resin grouts. The degree of intimate mixing required is not so critical as with epoxies, curing rates are faster and installation can take place at lower temperatures. The range of applications is enormous — the fixing of reinforcement starter bars, foundation bolts, machinery and base plates, barriers and safety fences, railway and crane rails, etc.

Resin bonded systems employing the larger bar diameters and lengths of several metres have also proved popular for rock bolting and ground anchor systems for example as shown in Fig. 7.6. Three basic systems are available:

(1) The inner end of the bolt is anchored with a resin capsule and the bolt shank subsequently tensioned against a bearing plate on the rock surface. A compressive force is thus applied to counteract forces acting to expand the rock mass. The tensioned bolt may be fitted with load indicating devices to enable any

|

Fig. 7.4. Fixings using encapsulated resins (Ref. 5). |

|

Load (tonnes)

Fig. 7.5. Load v anchor length for fixings in unreinforced concrete (courtesy of СВР Ltd). |

|

Fig. 7.6. Rock bolting in highway cutting. |

ground movement to be monitored. Fig. 7.7 shows typical end bonded lengths against maximum load for several rock types.

(2)

|

A bolt which may be a smooth or deformed bar is bonded over its complete length. The bolt is untensioned but since the hole is completely filled with cured resin it can offer good resistance to shear stresses. Spalling of the surface rock, which can render tensioned bolts ineffective, does not impair the performance of a fully bonded dowel. Further, the resin can act to provide corrosion resistance to the bolt as well as providing the necessary bond.

(3) The third system combines the merits of both the tensioned bolt and the fully bonded dowel. A fast setting resin is used for the end anchorage, thus enabling tensioning of the bolt before the slower setting resin, used over the remainder of the length, has gelled. The method combines permanent reinforcement of the ground with positive compression to minimise movement at potential slip planes within the rock strata.

2 сентября, 2015

2 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике