Apart from the use of resin adhesives to effect repairs to failed brick slips, perhaps the three most common applications in the repair and/or strengthening of masonry structures involve injection, the fixing of dowels and the use of bedding mortars. Resin injection is often used to stabilise deteriorating brickwork in listed structures. It involves drilling through the exposed mortar joints, setting in injection tubes and pumping in low viscosity resin (polyester or

|

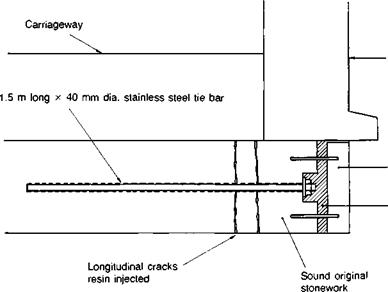

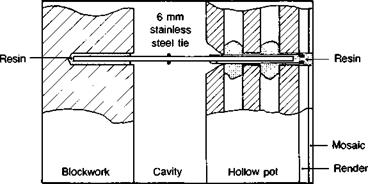

Fig. 6.26. Cavity wall tie (Ref. 31). |

epoxy) to consolidate loose rubble infill and to seal all cracks and voids in the brickwork itself.

There are a number of proprietary systems for resin bonded anchors which may be used to install additional ties in cavity walls. A typical fixing detail is shown in Fig. 6.26 which is based on a 6 mm stainless steel tie(31). This is bonded into pre-drilled holes in the hollow or solid masonry using resins formulated to suit the type of base material. For voided materials the resins may be injected via a mesh sieve or screen which enables a keying action to be obtained. Fig. 6.27 illustrates the steps to be followed in the fixing procedure. Similar details may be used for fixing steel anchors into unreinforced brick walls for improved strength and stability. Two — component, unsaturated polyester resins contained in separate cartridges which are subsequently mixed in a combined dispensing and mixing nozzle are commonly encountered. Further details of systems available may be found in Chapter 7 dealing with applications in new construction.

Applications are not necessarily confined to buildings. Nineteenth century masonry arch bridges have suffered damage and deterioration in recent years as a result of having to carry modern traffic loads. Defects in the form of longitudinal arch cracking and spalling of voussoir stones have been reported(32). Fig. 6.28 illustrates several uses of adhesives in a major refurbishment contract. 40 mm diameter stainless steel tie bars of length 1.5 m and bonded in resin were used to tie the edges of the arch barrels back to the centre.

3.

|

Beginning at the bottom, fill the screen tube with adhesive.

Fig. 6.27. Fixing of resin bonded anchors to masonry (courtesy of Hilti Ltd).

![]()

![]()

Sandstone indent fixed with stainless steel dowel bars

Sandstone indent fixed with stainless steel dowel bars

Epoxy mortar

Applications in repair and strengthening Longitudinal cracks were first filled by injection of a variety of materials depending on the crack width. Large cracks in excess of 15 mm width were injected using cement grout containing a nonshrink additive. A filled epoxy resin was used for cracks ranging from 1 to 15 mm wide whilst a low viscosity epoxy was used for the finer cracks. Replacement surface stonework was bedded on epoxy mortar and tied back into sound original stonework with 16 mm stainless steel dowel bars anchored using a very fast setting resin.

29 августа, 2015

29 августа, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике