7.1 Bearings and expansion joints for bridges

Perhaps the most well known application of resins in civil engineering is in the form of resin mortar for either bridge bearings or expansion joint nosings. In bearings the mortar is used as a bedding compound on which to seat rubber or steel bearing pads. These pads serve to transfer loads from the superstructure to piers or abutments and the stresses they resist are largely compressive in nature.

Expansion joints in concrete bridges were traditionally formed by the use of steel edging angles anchored or bolted into the concrete deck either side of the expansion gap. Such joints have a limited life due to disintegration of the supporting concrete under the action of traffic impact and they are very difficult to repair or replace. As a result resin mortar nosings were introduced on UK highway bridges in the mid 1960s but they too were not entirely free from trouble. The early nosings were based on relatively slow curing epoxy systems and a typical installation procedure is illustrated in Fig. 7.1(1). In due course other epoxy formulations began to appear and faster curing systems were introduced in an attempt to avoid the need for heating and testing in cold weather.

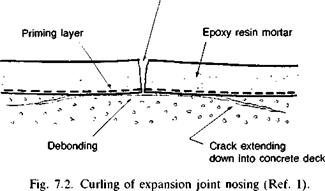

In the late 1960s transverse cracks began to appear in some nosings and in the following years hollowness and cracking became a major nuisance. Investigations revealed that the majority of faults were due to use of the faster curing systems, resulting in warping and curling as shown in Fig. 7.2. This occurs because of differential contraction following the exothermic reaction, the bottom of the nosing being restrained by adhesion to the concrete deck. On cooling the nosing curls and lifts at the transverse joints or shrinkage cracks, and may be accompanied by cracks extending down into the concrete deck.

In more recent years such difficulties have largely been overcome by careful formulation of the resin. This includes the use of resins with a slower cure rate, the use of larger size aggregate to allow

|

|

||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

|

||||||||||||

![]()

Fig. 7.1. Installation of epoxy nosing (Ref. 1).

|

Nosing lifting at shrinkage crack or transverse joint

|

heat to dissipate or by flexibilising the epoxy to permit some stress relief during cure. Polyester resins have also been considered and indeed used on one occasion. They have the attraction of their cure being less affected by low temperatures but the disadvantage of higher shrinkage and poor adhesion to damp surfaces. Polyurethane resin mortars have also been used successfully for a limited number of applications. They are cheaper than epoxies and can cure at lower temperatures but have a tendency to foam in the presence of water.

Despite the development of resin mortar technology in recent years such that many of the causes of the earlier failures have now been eliminated, the confidence of the industry has been severely dented and resin nosings are now a rarity in UK bridge construction.

30 августа, 2015

30 августа, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике