Cleaning and Pretreatment of the Surfaces to be Joined. To insure good adhesion of the adhesives, the surfaces to be joined must be cleaned before the adhesive is applied. Layers of grease, oil, and lubricant are removed by means of solvents or aqueous degreasing baths. Loose dirt and oxide layers can be removed by brushing. In many cases, the surfaces to be joined are rubbed down with emery paper or sandblasted to remove firmly anchored layers that would interfere with the bonding process or to enlarge the surface by roughening. Pretreatment processes are used additionally to increase the affinity for bonding or (adsorption) activity of the surface and even to impart an affinity for bonding to certain plastics. In general, acidic pickling baths and often combined acidic and oxidizing pickling baths are used for metals, generating defined oxide layers. Alkaline pickling baths are used relatively infrequently. In plastics that are difficult to bond, the surface is modified by chemical pretreatment processes that increase the surface tension of the plastics and, hence, also their wettability and bondability [55]. The so-called corona treatment, i. e, electrical discharge in the presence of air, is used primarily for pretreating plastics films and, in some cases, also metal foils.

In addition to the cleaning and pretreatment of the surfaces to be joined, primers are applied before the actual adhesive in individual cases, their function being to improve the adhesion of the adhesives and/or favorably to influence the resistance to aging and corrosion of the bond.

Adhesive Application. Water-based adhesives and pigmented solvent-based types should be stirred thoroughly before application to remove possible inhomogeneity. For two-component or multipackage adhesives exact dosage and homogenous mixing of the components is essential. The method of application of the adhesive determines the uniformity of the bond line, the thickness of the adhesive layer, and therefore the

|

|

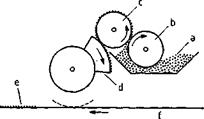

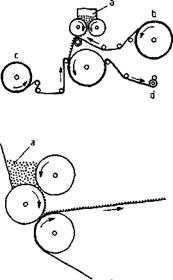

Figure 2. Application by segments

a) Adhesive; b) Dipping roll; c) Transfer roll; d) Rotating

segments; e) Applied adhesive; f) Substrate web quality and economy of the bonding process. The application method itself depends on the size and nature of the surface, the rheology of the adhesive, the required coating thickness, the number of components to be bonded and the speed of the process.

Manual application of the adhesives with toothed spatulas, blades, casting knives, or brushes is the simplest but least uniform method of application. Pasty adhesives can be applied from cartridges which are squeezed by hand or mechanical devices. This method is also used for moisture-curing polyurethane hot-melt adhesives with heated cartridges.

Low-viscosity adhesives are distributed over large areas by spray guns in the same way as paints (Fig. 1). The spraying process may involve the usual atomization with air or can be airless in the case of solvent-based adhesives.

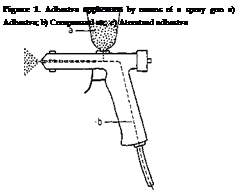

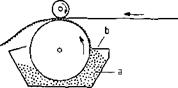

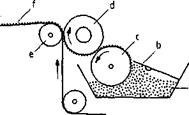

Rollers are a versatile application method and range from simple glue rollers fed from a reservoir to highly sophisticated systems with several rolls, suitable for hot-melt, solvent-based, water-based, and solvent-free reactive adhesives (Figs. 2 — 6). The coating thickness is regulated by the distance between the rollers, the friction between them (different rotational speeds) and/or by blades. By this means, it is possible to apply from 0.5 g/m up to > 20 g/m in a very precise operation.

Gravure rollers are used together with doctor blades for a constant coating weight over the width in a narrow range of thickness. Unless the entire surface must be coated with adhesive, slim rollers or so-called wheel applicators are used. If the adhesive is only applied at intervals or with interruptions, segment rollers or wheels, interrupted rollers, toothed wheels, profile rollers, rollers with moving segments, or plungers are used. In

Figure 3. Application by rolls combined with a blade a) Adhesive; b) Doctor blade

![]()

Figure 4. Application by a wheel applicator system a) Adhesive; b) Blade; c) Dipping roll; d) Shaft with wheel applicator; e) Backing roll; f) Coated substrate web

Figure 4. Application by a wheel applicator system a) Adhesive; b) Blade; c) Dipping roll; d) Shaft with wheel applicator; e) Backing roll; f) Coated substrate web

Figure 5. Coat application of hot-melts by rolls (System Pack 400/Kroenert)

a) Hot-melt adhesive; b) Roll I; c) Roll II (cover web); d) Winding up roll

Figure 6. Reserve roll coating system (System Pagendarm) a) Adhesive

addition, blade coating and airbrush coating are used. Hot-melt adhesives must be melted prior to application by rollers. The adhesive is usually transferred from the rolls to the substrates by direct coating in the machine direction. In some cases, reverse-roll coating (Fig. 6) has advantages, especially for low-viscosity adhesives.

Curtain coaters are used for applying adhesives over wide areas by passing the web below the nozzle of the tank (Fig. 7). Highly viscous hot-melt adhesives and thermoplastic polymers are applied from wide-slot nozzles to form a weblike film on the substrate.

|

|

Typically, hot-melt adhesives for folder packaging are liquefied in melting tanks or drum melters and then pumped through heated hoses to the application nozzle. The piston pumps or gear pumps generate sufficiently high pressures to allow contactless application or spraying.

The porous coat system (Nordson) allows the application of discrete, random, and open patterns of hot-melt adhesive to substrates such as films, papers, fabrics, and nonwovens. With the control coat system, hot melt adhesives are applied continuously or intermittently by air-controlled nozzles without contact to the substrate. This technique is used as well for reactive hot-melt adhesives such as moisture-curing polyurethane hot-melt adhesives.

For temperature-sensitive substrates and prolonged open times, gases are incorporated in the melt under pressure. As a result, a hot-melt foam is formed during application [56].

The application units of solvent-free laminating machines consist of three or four rollers with differential speeds to lower the coating weight to 1.5 g/m2, enabling machine speeds from 250 up to 500 m/min.

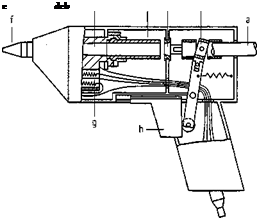

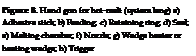

Relatively simple handguns (Fig. 8) are used for the workshop or do-it-yourself application of hot-melt adhesives.

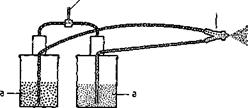

Metering and mixing units (Fig. 9) of various constructions (gear pumps, piston pumps, static mixers) are used for the application of two-component adhesives and provide precise dosing and mixing even at elevated temperatures (70 °С).

Figure 9. Two component mixing equipment a) Tanks with metering pumps; b) Compressed air; c) Mixing gun

![]()

![]()

![]()

Anaerobic reactive adhesives and cyanoacrylate adhesives are applied by means of special metering units that dispense small predetermined quantities at the required time intervals.

Anaerobic reactive adhesives and cyanoacrylate adhesives are applied by means of special metering units that dispense small predetermined quantities at the required time intervals.

Joining, Fixing, Drying, and Hardening. After applying the adhesive to one or both surfaces, the substrates have to be fitted together within the open time and fixed until the bond is sufficiently firm. The pressure that has to be applied for bonding is determined only to a minor extent by the adhesive and largely depends on the geometry, nature, and deformability of the substrates and by its recovery forces.

The pressure for joining and fixing to give whole-surface contact can be very high, particularly in the case of large-area bonds, although the adhesive itself does not require such high pressures, apart from contact and hot-setting condensation adhesives. The necessary pressure is usually applied by pressure rollers, laminating rollers, or braces and presses.

The setting time and hence the fixing time can be shortened by heating. Warmsetting adhesives require certain minimum temperatures and times for curing. The energy required may be supplied by recirculating air ovens, drying tunnels in laminating machines and lacquering ovens, by radiant heaters, and by contact heating in heated presses or laminating rollers. Inductive heating of metal-to-metal bonds and high-frequency infrared heating of aqueous adhesives are also used occasionally. Within the last years UV-curing adhesives have been introduced, while electron-beam-curing adhesives are still in the development stage.

Polycondensation adhesives must be subjected during hot hardening to an external pressure that is higher than the vapor pressure of the cleavage products formed during condensation. Accordingly, these adhesives are applied in heated presses or by using pressure bags in heated ovens. The vacuum/pressure process in heated autoclaves is preferably used for uneven, three-dimensional surfaces [57].

A special case of bonding is the heat-sealing of previously applied heat-seal adhesives. Such coatings are converted by heat into a tacky state and bonded by the application of pressure. Thermal activation is carried out by heated sealing bars or plates, hot air, and sometimes by IR radiation.

High-frequency welding is used for special applications, in which cases the necessary heat is generated by the interaction of high-frequency radiation with the dipole moment of the pre-applied heat-seal adhesive itself.

23 сентября, 2015

23 сентября, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике