In the 1980s, the development of reactive polyurethane hot-melt adhesives for unsewn binding was an important innovation for the graphics industry and enabled the print finishers to use unsewn binding techniques for products that hitherto had been ‘impossible to bond’ [40]. Reactive polyurethane hot melts are the adhesive of choice whenever using papers that are difficult to bond, whenever products are exposed to high temperatures (e. g. a road atlas on the hat rack of a car), and whenever high page pull and page flex values are required due to special stress. Polyurethane hot melts are tailor-made polyurethane prepolymers with reactive end groups. Following application, these end groups are subject to a chemical reaction under the effect of air humidity and/or paper moisture, resulting in a large increase in molecular weight. The high adhesive capacity of the prepolymers provides for excellent adhesion to the paper edge. Following chemical reaction, polyurethane films are highly cohesive and provide outstanding durability, making them immune to the migration of mineral oils from printing inks, and giving them a good resistance to aging. At present, the use of reactive polyurethane hot melts is common practice in bookbindery, providing for high machine speeds of more than 10 000 books per hour. It is essential to adjust the machinery to the requirements of reactive polyurethane hot melts to make bookbinding with PU resins successful. For example, coated glue reservoirs are needed so that the sticky adhesives can be easily removed at cleaning. Another key factor is an optimized temperature control, because reactive adhesive systems are clearly more demanding with regards to thermal stress. Recent years have seen the development of special nozzle systems for the application of reactive polyurethane hot melts in unsewn binding.

However, it is not only the applicators that must be modified, but also the melting equipment. As polyurethane adhesives crosslink under the effect of moisture, it is essential to keep them away from air humidity during manufacture, transport and, if possible, also during further processing. One possibility is to deliver them in drums emptied with so-called ‘drum melters’ (Figure 8.40).

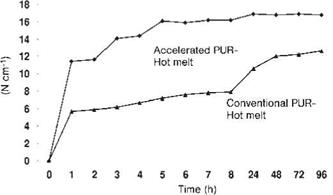

Drum melters provide for a durable sealing against air humidity. ‘Melting on demand’ makes it possible to limit the thermal stress to which the adhesive is exposed, with only the amount of adhesive actually needed at a certain time being molten. Although the reaction times of the first-generation reactive PU resins were rather long, at present these highly accelerated systems enable unsewn-bound products to be ready for use within a few hours (6-16 h) (Figure 8.41).

These systems stand out for their low processing viscosity, good initial adhesion and, in particular, for their excellent viscosity stability (which is essential for tank melters) during processing.

|

Figure 8.40 Drum melter. |

However, as reactive polyurethane adhesives take advantage of the reactivity of isocyanate groups, free (monomer) isocyanate exposure and emissions must be controlled. Isocyanates are classified as sensitizing to the skin and respiratory tract, and most PU resin adhesives must be categorized as hazardous preparations, indicated by the hazard symbol Xn (‘harmful’). As many measurements by professional associations have demonstrated, emissions occur not only during the processing of the adhesives but also when changing or cleaning the drums. By taking precautions, however, conventional products can be processed safely. Nonetheless, alternative options have been developed, brought forth by the ever-increasing safety

|

Figure 8.41 Curing periods of conventional and accelerated polyurethane adhesives. |

awareness of the bookbinders. New adhesives that contain substantially less (<0.1%) monomer isocyanate than do conventional adhesives have been developed, without loss of any of the positive characteristics ofPUs such as low viscosity and low increase in viscosity, high initial strength, and rapid crosslinking mechanism. In these products, the isocyanate concentration remains below the limit value from which the products must be categorized as hazardous preparations according to the regulations stipulated by legal authorities in the EU countries. With good processing practice, these products emit up to 90% less isocyanate vapors than do conventional reactive polyurethane hot melts.

Reactive polyurethane hot melts suitable for the inline manufacturing of rounded, unsewn-bound products have also been developed in recent years. Until then, problems had occurred with the relatively low-molecular-weight prepolymers because, immediately following application, their cohesive strength was not high enough to withstand the rounding process. This demand now can be met with so-called ‘dual cure systems’; these are reactive polyurethane hot melts that cure not only under the effect of moisture, but also under irradiation with UV light. Within seconds after application, curing under UV light induces sufficient strength to start the rounding process and to yield high-quality results. The adhesive film is further stabilized by the subsequent reaction of the isocyanate groups with moisture.

7 декабря, 2015

7 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике