The use of bonding in the shipbuilding industry extends to yacht, charter and military applications. In yacht construction, bonding has become an indispensable

|

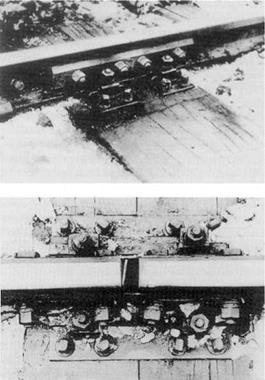

Figure 8.12 An insulated rail joint with screws (right) and additionally adhesively bonded (left) at —28°C. (Photo courtesy of Henkel). |

construction technique. As in the construction of motor homes, the cost factor is very important here, and consequently plastic composite materials are used in the majority of cases, to a point where entire ship structures may be manufactured by this method. Adhesives are also used for sealing purposes, with ship hulls, stringers and frames being bonded with two-part epoxy adhesives.

For charter applications, new construction techniques are increasingly being adopted, where in the past ship builders have conventionally regarded steel as being ‘solid’. However, they are increasingly seeking alternatives in construction technology and, as a consequence, lightweight materials such as fiber-reinforced plastics are increasingly being used for the structures of very large, an example being in the construction of swimming pools.

One interesting example of the use of adhesives in charter applications is the building of a high-speed ferry that was 60 m long [13] and capable of transporting about 1000 passengers at a speed of 40 knots (ca. 75 km h—1). This performance could only be achieved by using lightweight constructions, with the hull consisting of profile-reinforced integral aluminum plates with polycarbonate windows fitted by means of glass fiber-reinforced adhesives.

8.3 Building Industry j 237

9 ноября, 2015

9 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике