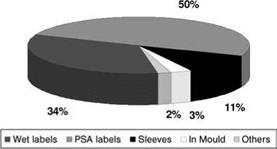

Although, currently the European label market (Figure 8.33) is dominated by precoated pressure-sensitive labels, this market share of about 50% is expected to grow further.

Self-adhesive labels are usually applied as tags, they adhere well to the majority of materials, and they can be made from either papers or plastic films. Precoated PSA labels are widely used in the cosmetics and cleaning products industry, but in the beverage industry their use is limited to products of high value or to special promotions, as they are rather expensive. Another factor which has limited the use of self-adhesive labels in the past has been the performance of the dispensers, although today dispensers can perform at 60 000 containers per hour. Precoated PSA labels are manufactured by coating adhesive onto ribbon-shaped base materials such as paper, plastic films or metal foils with an adhesive layer thickness of 18 to 50 pm.

The adhesives applied for this purpose are based on different technologies. Besides the natural rubber-based PSAs (which usually are available as solvent-containing

|

|

systems) and thermoplastic rubber or acrylate-based PSAs, dispersion adhesives are becoming increasingly popular. Acrylate dispersions in particular have remarkable technical properties; for example, they are a transparent labeling material, and precoated PSAs are increasingly being used for so-called ‘no-label look’ labels. They provide for an especially alluring container design since, at first glance, these transparent film labels (which are only partially printed) appear as though they have been printed directly onto the containers. The adhesives used for this purpose are totally transparent and not visually discernible at all.

In addition to the conventional water-resistant PSA labels, plastic film-based label materials are available that are suitable for reusable containers. In this case, lye — soluble PSA coatings are used which lose their adhesion capacity when exposed to the conditions of a bottle cleaning machine and are removed together with the plastic base material.

1 декабря, 2015

1 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике