When fixing the glass elements, they must be fixed in the desired position as rapidly as possible. Hot melts (also known as ‘optical pitch’, ‘sealing wax’ or simply ‘wax’) are very popular owing to their high curing rate and solubility in organic solvents.

In optical components, strains are induced by shrinkage of the adhesive during solidification, as well as by the different coefficients of thermal expansion of the materials during cooling. Inorganic fillers such as chalk powder or quartz filler can reduce shrinkage of the adhesive, while a flexible resin matrix can help to minimize the strains caused by differences in thermal expansion during cooling. The flexibility of the matrix is limited, however, due to the creeping behavior of the resins, which may have an effect on the alignment of the optical elements during the curing process. Due to the undesired creeping behavior of soft thermoplastic resins, hot melts cannot fully meet the requirement of placement accuracy and minimization of strains in optical components.

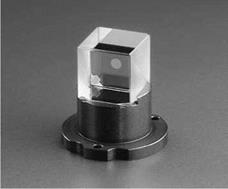

Reactive adhesive systems also allow the components to be fixed at room temperature, although after curing they are required to have a low resistance to solvents. Besides acrylics that crosslink at room temperature, modified acrylics which set under the effect of UV light are used (Figure 8.62).

After processing, the adhesive must be decemented rapidly, without causing any harm to the sensitive optical surfaces (see Section 8.17.5), a requirement that cannot be fulfilled by conventional adhesives. For this purpose, UV-setting adhesives are available that have been modified in such a way as to debond as soon as they are heated in an aqueous soap solution, or as soon as they are immersed in organic

|

Figure 8.62 A bonded beamsplitting cube. The prisms are glued together with optical cement, and the cube is bonded to the mount. (Photo courtesy of Swissoptic AG). |

solvents. The resistance to aqueous solutions, however, must be high enough so as to withstand exposure to the aqueous emulsions used in the manufacturing process. Therefore, the use of UV-setting adhesives is a very sensitive process.

8.8.3

25 декабря, 2015

25 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике