In many applications, acrylic-based high-performance PSA foam tapes have replaced mechanical fastening methods such as joining by screws, riveting, clipping and spot-welding. Over the past 20 years they have become widely accepted in numerous applications. Owing to their viscoelastic behavior, they absorb dynamic forces and vibrations to a much higher extent than do mechanical joints. They can also compensate for differences in the linear expansion ofthe joined materials up to three times their own thickness, making it possible to save both weight and production costs. A safe, reliable and performing joint is created owing to high tack, immediate processability, stress-free joining of dissimilar materials, high resistance to elevated temperature, and the availability of customized die-cuts (Table 8.3).

High-performance foamed adhesive tapes are a virtually inseparable unit consisting of an acrylic closed-cell adhesive core and two functional adhesive surfaces.

|

Table 8.3 Advantages of high-performance PSA tapes (foamed).

|

Unlike the case of conventional foamed adhesive tapes, the continuous viscoelastic adhesive allows a permanent, stress-free joint to be created. These systems are based on acrylic copolymers containing C-C single bonds that have a very high resistance to energy in the form of heat or UV radiation, and excellent resistance to chemical attacks. This property makes them particularly well suited to the production of conveyor belts that are exposed to high temperatures, for example in shrink tunnels in the food industry. These adhesive tapes have permanent resistance to elevated temperatures; indeed, some of them can shortly resist temperatures of up to 260 °C.

With acrylic-based high-performance PSA foam tapes, a wide variety of materials with different surface properties can be joined, with the forces always being distributed evenly. Unlike mechanical joints, adhesive tapes can absorb shear forces owing to their viscoelastic behavior. When the temperature increases by 50 °C, the linear expansion of aluminum is 1.15 mm (relative to 1 m) and that of steel 0.85 mm; this results in a difference of 0.3 mm, which is easily compensated by the tape.

Adhesive tapes also have excellent adhesive capacity. On steel, for example, they have a peel strength of 120-450 N per 100 mm and a tensile shear strength of 42-69 N cm~2.

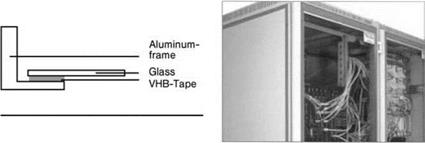

Acrylic high-performance PSA film tapes are transparent; foam tapes are available in black, white, gray or transparent, with thicknesses ranging from 0.05 to 3 mm and widths from 6 to 1200 mm. Transparent tapes play an important role in new production techniques, notably in the glass industry. Solar modules are also produced with the help of acrylic-based high-performance PSA tapes; an example is the solar modules (which were installed to walk on) in front of the glass dome of the Reichstag Parliament Building in Berlin. The transparency was tested in an accelerated aging test by exposing them to high temperatures and intense UV radiation for 3000 h, during which time the transparency decreased by only 1% (from 88.2 to 87.3).

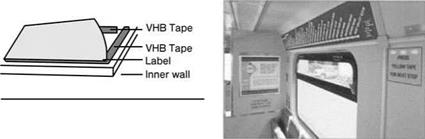

Innovative solutions are also made possible by the use of high-performance PSA foam tapes in other industry sectors. For example, they are used for roof structures of trailers, in ceilings with integrated cooling systems, or in facade construction (Figures 8.51 and 8.52). At the Jumeirah Beach Hotel in Dubai, a total of 60 000 m of PSA tape was used when constructing the building. In truck construction, the roof panel is often directly bonded to a load-bearing structure without screws, rivets or spot-welding and, as there are no boreholes, there are no points of attack for leakage or corrosion. In this way, when bonding the stiffener profiles of side

|

Figure 8.51 The fastening of a label in a railway carriage (VHB® tape; 3M). |

|

Figure 8.52 Adhesive bonding of glass windows (VHB® tape; 3M). |

panels, for example of trucks, a uniform undamaged surface is created which is ideal for the application of decorative PSA films as there are no awkward screws or rivets. In such applications PSA tapes also help to reduce noise.

Today’s ever-smaller components do not offer enough space for conventional fastening methods. For this purpose, customized die-cuts are available that have shock-absorbing and sealing properties for later use. They can also be used, for example, in the sealing of switch cabinets or underwater cameras.

18 декабря, 2015

18 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике