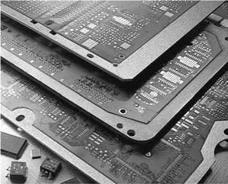

Transfer tapes with different functionalities are frequently used in the electronics industry to bond dissimilar surfaces (Figure 8.60). Acrylic-based PSA tapes offer exceptional holding forces as well as excellent durability, sealing properties and shock resistance. They are used, for example, in the assembly of circuit boards and for the bonding and sealing of underwater cameras.

Transfer tapes with very low concentrations of monomers, organic acids and organometallic compounds are available for applications that are very sensitive to contaminations. These products are employed, for example, in the bonding of electronic components in clean room environments and for the assembly of hard disc drives. Optically clean transfer tapes with more than 99% light transmission are

|

Figure 8.60 Circuit boards bonded to aluminum sheets. |

used for the bonding of displays and touch screens to ensure excellent transparency and accurate colors.

8.7.1 Spacers

Spacers composed of PSAs coated on polymer films allow a certain width to be maintained between electronic components. Figure 8.61 shows a spacer for foil keypads. The spacers are required to be flexible and to compensate for external stresses and strains.

8.7.2 Labeling

Electronic components or circuit boards are labeled by means of products that are resistant to high temperatures and that are printable by thermotransfer. The labeling

|

Figure 8.61 Spacer for membrane keypads. |

is required to be maintained even after processing of the components, particularly after the soldering process. Whereas, conventional soldering was performed at temperatures of 230 °C, the components and labels must now withstand temperatures of up to 260 °C with the new lead-free solder. Smart labels have integrated chips and an antenna providing for a contact-free labeling, for example, as RFIDs.

23 декабря, 2015

23 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике