Plastic materials, particularly plastic films that are converted into flexible packages, are becoming increasingly popular in the packaging sector.

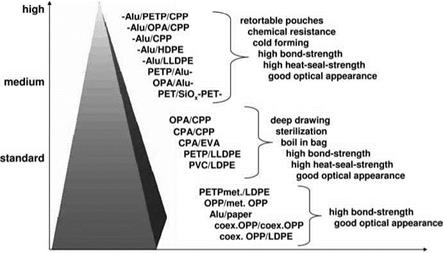

Flexible packages are manufactured from monofilm or, more often, from multilayer film made from different plastic films or from combinations of plastic films, metal foils or paper. The underlying principle is the combination of materials with selected properties to achieve a performance synergy effect, including temperature stability, barrier properties, mechanical strength and alluring appearance (Figure 8.25).

A multitude of materials is used for packaging composites, ranging from polyethylene (PE), polypropylene (PP) and paper to polyvinyl chloride (PVC), polyvinylidene fluoride, cellulose film, polyester, polyamide and aluminum. The plastic films are

|

|

|

Figure 8.25 Laminating composition. |

frequently vapor-coated with aluminum or SiOx, or coated with polyvinylidene chloride (PVDC) or acrylic to enhance the barrier or light protection properties, respectively.

A great number of special laminating adhesives have been developed for different applications [29]. One important group here are the polyurethane adhesives (PU resin or PU laminating adhesives), which are based on aromatic or aliphatic isocyanates, respectively (see Section 5.6). Although PU resin laminating adhesives containing solvents have been used in large quantities, the production of composite materials using solvent-containing PU resins is very energy-intensive due to the drying process, the large amounts of raw materials required for the adhesives, and the amount of solvent added. These systems are suboptimal in terms of their sustainability, even if the production system is coupled to a solvent recovery system. In order to relieve this problem, high-solid and solvent-free PU resin laminating adhesives have been developed, starting with one-part systems which set under the effect of moisture. As NCO-terminated polyether or polyester prepolymers, they depend on moisture either to be available either in the air or to be added during lamination to cure into a polyurea/polyurethane in a crosslinking process. At present, these systems are used only for paper composite material, such as oriented polypropylene laminated with paper. To avoid the limitations set by solvent-free one-part systems crosslinking under the effect of moisture, two-part systems have been developed which are usually based on polyester or polyether with a polyisocyanate hardener. Both parts are liquid at room temperature and can be processed at low temperatures, preferably between 25 °C and 45 °C. Recent years have witnessed the development of systems with processing temperatures between 40 ° and 70 °C. This new generation of solvent-free laminating adhesives combines the advantage of a high solid system (initial adhesion or ‘tack’) and that of a solvent-free liquid phase (easy processability). The prepolymers are synthesized in such a way that a fast curing can take place in

|

Electron beam curing |

Coating |

Laminating |

Electron beam |

Fast curing |

|

UV radicalic |

Coating |

Laminating |

UV light |

Fast curing |

|

UV cationic |

Coating |

UV light |

Laminating |

Curing in 24 h |

|

Figure 8.26 Curing methods. |

several stages, starting with the desired and complete reaction of the monomers (Figure 8.26).

For sterilizable aluminum/plastic film composite materials, solvent-free laminating adhesives based on aliphatic isocyanates have been developed. These so-called ‘aliphatic laminating adhesives’ are processed at 70 °C with conventional lamination machinery, dosing and mixing devices, respectively. A significant advantage here is the lack of aromatic isocyanates that plays an important role with regards to food-law regulations. One feature of all the above-mentioned PU resin laminating adhesives that is the prerequisite for their suitability for laminating purposes is that, within the composite material, thermal and mechanical resistance only fully develops when they are completely cured. The curing period may be one week or longer, depending on the type of adhesive used, the film/foil combination, and the curing temperature. Increasing the temperature shortens the curing period. In either case, the time needed to produce composite materials (including printing, cutting, etc.) is of the utmost importance, as the capital tied up by long curing periods may become a significant expense, especially for companies with a high competitive pressure. It is not surprising, therefore, that there is a strong desire for a laminating adhesive that cures so to speak ‘on command’. One possibility would be to use radiation-curing systems, which have the advantage of achieving a rapid initial adhesion (‘green strength’). When comparing the different laminating adhesives, the ‘green strength’ of solvent-free systems is clearly considerably lower than that of systems containing solvents. This situation can be explained by a significantly lower molecular weight range and distribution, respectively, and is dictated by the low viscosity required to apply the adhesive without further dilution with solvents. Laminating adhesives which set under the effect of irradiation can be applied without solvents and at low viscosity, and provide for both a high ‘green strength’ and a very rapid attainment of ultimate strength following irradiation. The different crosslinking mechanisms of radical and cationic polymerization allow different processing steps to be performed with regards to irradiation and lamination (Figure 8.26).

Another possible way to avoid solvents is to use aqueous laminating adhesives; these systems are based on one-part or two-part polyurethane or acrylate dispersions, respectively. They can be processed on existing lamination machinery, and require only a minor investment for a retrofit. Aqueous systems also stand out for their high ‘green strength’ and fast curing; neither do they leave any solvent residues in the composite material. One disadvantage, however, is the large amount of energy needed for the drying process. Unfortunately, waterborne adhesives generally do not provide the end-use performance level of solvent-containing or solvent-free systems.

27 ноября, 2015

27 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике