A most versatile option to make an electrical interconnection between two or more contact points is to use electrically conductive adhesive films that contain graphite fiber nonwovens or metal/metallized particles. These not only allow the use oflighter materials and flat design, while improving the reliability of the finished products

|

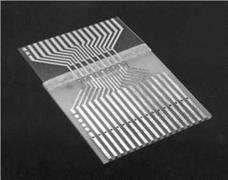

Figure 8.59 A polyethylene terephthalate (PET) circuit module bonded to a printed circuit board. |

(Figure 8.59), but also help to reduce costs with regards to materials and processes. Depending on the current flow, a distinction must be made between isotropic and anisotropic electrical conductivity.

Isotropic adhesives are XYZ-axes electrically conductive; that is, the current flows not only through the adhesive thickness (Z-axis) but also in the plane of the adhesive (XY — axes). Isotropic adhesives contain, for example, electrically conductive fibers that interlock in such a way as to allow interconnection in the X, Y and Z directions.

Anisotropic adhesives allow interconnection through the adhesive thickness only (Z-axis); that is, the current only flows in one direction. Anisotropic adhesives are filled with conductive particles, for example high-temperature curable adhesive films filled with silver, nickel or gold particles. The adhesive acts as an insulator between the particles.

First-generation anisotropic adhesive films were specifically designed to make the manufacture of liquid crystal displays (LCDs) easier because the ‘fine’ electrical contacts of the flexible circuit boards could no longer be soldered. Another typical application is the bonding of flexible silver-paste printed polyester circuit modules to rigid plates. Adhesive films are also suited to the bonding of flexible circuit modules to flexible membrane switches. Products designed for this purpose also offer the benefit of a fast processing because they are slightly pressure-sensitive before crosslinking at 130 °C. However, the majority of anisotropic films require special cooling during storage and transportation below 0 ° C because they are very sensitive to temperatures.

Depending on the desired application, anisotropic adhesive films can contain either hard or soft particles. Hard particles are suited for the interconnection of flexible to flexible or flexible to rigid plates, and are embedded into the conductive path by means of pressure; this increases the contact area and obtains good electrical properties. Soft particles are used for flex-to-glass interconnections — that is, the bonding of flexible circuit modules to glass substrates (LCDs). When they come into contact with hard surfaces, they deform and improve the electrical properties. Selection of the correct system requires a consideration to be made of the type of adhesive and the size and concentration of the particles, as these parameters have an influence on the electrical and mechanical characteristics, the bonding process, and the fields of application. Put simply — the more particles in the matrix, the better the conductivity; the less particles, the better the adhesion.

Thermoplastic anisotropic adhesive films have special features allowing smart cards to be converted into multifunction cards. Besides conventional chip bonding, they allow the integration of radiofrequency identification (RFID) antennas, finger print sensors and displays into smart cards. As the processing time of the adhesive films is very short (maximum 3 s), roll-to-roll lamination is possible. In addition, unlike high-temperature curable adhesive films, these adhesives do not require any cooling during storage and transportation.

8.7.3

21 декабря, 2015

21 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике