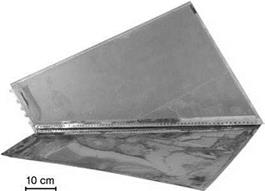

Large-area delamination ofthe adhesive bonding between the aluminum outer cover sheet and honeycomb structures of the tail unit of aircraft resulted in several cases with a similar damage pattern (Figure 7.67). Due to these delaminations the outer cover sheets were even lost during flight, with both the bottom side and upper side of the cover sheets of the tail unit having been affected. The surfaces uncovered by delamination revealed a purely adhesive failure pattern and minor signs of aging by moisture penetration (Figure 7.68).

From the large-area failure of the bonding, it was deduced that the damage must have been caused by adhesive failure due to impaired adhesion as a consequence of

|

Figure 7.67 Delamination of outer cover sheets in the tail units of an aircraft. |

contamination of the adherents. Surface analysis, however, did not provide any conclusive evidence for this assumption. It should be noted that surface analysis methods with sensitivity in the atomic monolayer range are preeminently well suited to making a statement on well-defined surfaces under laboratory conditions. Surfaces in an undefined aging condition, as they are encountered in practice, however, cannot be analyzed conclusively without further information.

In the present case, inaccurate temperature control with a too-low curing temperature during the autoclave process was found to be the cause, and led to several similar cases of damage. This was indicated by the following considerations. Impairment of adhesion by a contamination of the adherents was not likely. This could be deduced from the results of surface analysis, and from the fact that a 180 ° C hot-curing foil adhesive was used. Indeed, higher temperature curing adhesive systems are expected to provide adequate contamination tolerance. A failure surface showing significant parts of cohesive failure would have been expected to occur. However, the large-area adhesive failure mode indicated that the foil adhesive must not have been able to wet the adherents properly at all, most likely due to a too-low

|

|

|

Figure 7.69 Heat-initiated delamination in a tail rotor blade. |

curing temperature. Under the manufacturing conditions assumed, inadequate wetting due to an aged and precured adhesive could be excluded because hot-setting adhesives react very slowly. The occurrence of few, but identical, cases of damage was best explained by a defective autoclave process causing a too-low curing temperature and a resultant high viscosity of the adhesive film such that it could not properly wet the adherent surfaces.

7.8.5

1 ноября, 2015

1 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике