In modern vehicle construction, high priority is given to weight reduction, improved long-term mechanical strength and corrosion resistance, increased comfort, crash resistance and higher body rigidity. Intelligent lightweight constructions can only be obtained by consistently using a material mix of steel, light metal and plastics which may be joined by conventional thermal and mechanical joining techniques, but only to a limited extent. It seems that bonding is a competitive joining technique with specific advantages for the above-described purposes.

The most important areas of application for bonding in the construction of vehicle bodyworks are direct glazing, hem-flange bonding and antiflutter bonding, the bonding of plastic components, and the structural bonding of bodies.

Direct Glazing Direct glazing constitutes the fitting of fixed glass panes with PU adhesives (Figure 8.7). In the majority of cases, one-part moisture-setting products are used which create an elastic joint between a painted body flange (finishing paint or cataphoretic dip coating ‘e-coat’) and the glass. The glass side is pretreated with an adhesion-promoting glass primer that provides for adequate light rejection. If a sufficiently low UV transmission is obtained by the ceramic screen process printing on the border of the pane, then transparent glass primers may also be used on occasion [8-10].

A conventional glazing system consists of a glass promoter (purpose: cleaning, adhesion promotion), the black glass primer (adhesion promotion, light rejection), the adhesive itself, and the paint primer (adhesion promoter for the paint side). The glass promoter contains silanes, and is especially efficient when applied as a thin coat. Therefore, it is common practice today that the promoter is wiped-off with a clean cloth after application (wipe-on/wipe-off process).

The one-part PU adhesive sets with moisture, taking the reactant (i. e. water) from the ambient air. The setting speed is determined by the diffusion of water vapor, with

FMVSS 212

Quality

Body

stiffness

Figure 8.7 The different functionalities of direct glazing in cars. FMCSS 212 is a security standard (see text; CW is the factor of air resistance).

low absolute ambient humidity delaying the setting process. Although about 20 years ago, metered water pastes were used in North America, so that the setting process was independent of the climate in the manufacturing plant, these have now virtually disappeared from the market because the dosage and mixing was labor-intensive.

Occasionally, the adhesive joints are created directly on the e-coat. In this case, after e-coat curing, the bonding area must be covered temporarily before any further painting process can take place. This additional stage is justified as e-coating offers a very well suited adhesion area because e-coats adhere well both to steel and to the glazing adhesive. Very little variety exists among e-coats in car manufacturing, although the various types and colors of paint require extensive adhesion testing. Furthermore, each additional paint coat represents another interface that may become a potential inherent weakness as to the adhesion forces and long-term resistance. The e-coat bonding area is covered by special adhesive tapes or polyvinylchloride (PVC) plastisol adhesives which must be easily detachable after curing of the finishing paint, without leaving any residues. When the tapes have been stripped off the area is left clean and perfectly suited for bonding with the glazing adhesive.

Direct glazing was first introduced in the United States during the early 1970s. Notably, in the event of a crash the pane will remain fixed in the flange, thereby complying with US safety standard FMVSS 212; this is in contrast to the rubber profiles which were previously used to fix the pane in the flange, and which tended to fail on impact. In cars fitted with airbags the bond must also be capable of absorbing the forces when the airbag impacts on the inner side of the windshield.

In addition to its safety functions, direct glazing offers the following benefits:

• the possibility of automatic application

• a small gap width between pane and flange for improved aesthetics and lower drag coefficient

• a distinct increase in torsion resistance through integration of the glass into the body structure

• highly reliable tightness

• virtually no glass cracking and breakage during manufacture

The tensile strength of the cured adhesive film is approximately 6-10 MPa, with a stretch at break of several hundred percent, and a physical shear modulus of around 3 MPa. However, it is common practice to measure the shear stress-shear deformation value at a shearing of 10%, using a tensile shear specimen with thick adherents according to DIN 54451, with a higher adhesive thickness that is similar to conditions encountered in practice. By using this test method, lower values are obtained. The value issued is not a ‘true’ shear modulus but rather needs to be exactly standardized. Only those values obtained with the same thickness of adhesive coat, the same rate of deformation, and the same bonded area may be compared. For example, the effective rate of deformation of an adhesive coat of 6 mm will be only one-third of that of an adhesive coat of 2 mm at the same speed of the crossbeam of the tensile testing machine. However, above the glass transition temperature (Tg) all polymers basically have a viscoelastic behavior, and therefore the mechanical

properties depend on the deformation rate. Hence, the two test results can no longer be compared, even if the bond-line thickness is taken into consideration when assessing the measurement of the shear stress-shear deformation value.

The Tg of the cured adhesive is lower than —40 °C, so that the mechanical properties will hardly change within the whole range of the operating temperature.

Since the introduction of direct glazing, the basic design of the system has remained largely unchanged, and pane-fitting technologies that differ fundamentally from the firm (but elastic) bonding method are unlikely to be developed in the near future. Nonetheless, some processing details have been modified, not only improving the physico-mechanical properties but also facilitating the application of these systems at the assembly line:

• Hot application systems; after joining, the viscosity of the systems increases on cooling. This is partly enhanced by a crystallization of polymer components, and results in a good resistance to slipping off; consequently, auxiliary assembly tools may be dispensed with.

• The shear modulus is increased by a factor of 2 to 3; without any modification ofthe total weight, this further increases the torsion resistance of the body.

• Considerable improvements of the build-up of adhesion have been obtained with new paint systems that are more difficult to bond.

• More robust systems without any glass promoter or paint primer are used.

• Special two-part products accelerate the setting process and sometimes considerably reduce the influence of ambient moisture on curing.

• Glass primer products are already applied by the glass manufacturer and preserve their adhesion-promoting effect for months.

• Adhesives with low electrical conductivity prevent contact corrosion when joining metals that are less noble than carbon. With regards to strength and rheology, carbon black is used in adhesives as a highly efficient filler. Specific direct-current resistivity is used for assessment. This is useful, for example, when the insulating paint of an aluminum body is damaged during pane replacement. The complex impedance is also required to be sufficiently high, as radio antennas are often integrated into the panes.

For repair purposes, or for the recovery of end-of-life vehicles, the bonded panes are removed using vibrating cutting tools, or they are cut through with a high-strength steel wire. Adhesives that allow the joint to be easily debonded are currently under investigation, but the concepts developed to date have been largely unsatisfactory (see Section 8.16.5).

Safety at Work and Environmental Protection The noncured adhesive is mainly composed of a PU prepolymer, extremely low-volatile plasticizers and fillers as well as monomeric isocyanates in low quantities which react with the ambient moisture during the curing process. The isocyanate type used has an extremely low volatility

(vapor pressure at 20 °C: 0.476 x 10~6kPa). With correct handling, no traces have been detected in the ambient air even when using refined analysis methods.

In general, highly volatile solvents are not used for adhesives. These adhesives are safe to use provided that all mandatory regulations, ranging from storage and processing to disposal, are observed.

Glass Repairs The most important differences compared to OEM are as follows:

• Bonding onto the former adhesive surface, freshly cut during removal of the damaged pane. This surface is a good adhesion base for the repair adhesive. The preparation of the glass side is performed in a similar manner as during the OEM process.

• Priority is given to a speedy build-up of strength, influenced as little as possible by the ambient moisture, in order that the vehicle is returned to the road as soon as possible; therefore, two-part adhesives are frequently used.

Preference is given to repair systems that have a lower viscosity in order to allow hand application with a pistol. The functional characteristics, however, are required to correspond to those of the original quality (strength, modulus, electrical conductivity). The processing robustness is expected to be even higher, which allows the repair to be made at the roadside rather than in special repair shops.

Direct glazing has been the first high-volume and safety-relevant application in vehicle construction to prove the excellent performance of bonding as a joining technique, thus building confidence for further, high-demand fields of application. Adhesive systems that are comparable to direct-glazing products are used to bond sunroofs and roof modules. In particular, when joining dimensionally large adherents and material mixes (e. g. metal with plastics), the high flexibility and ductility of these systems represent important advantages since the different coefficients of linear expansion make joining difficult. In bus and truck construction, besides direct glazing, a similar application might be in the bonding of glass fiber-reinforced plastic (GRP) bus roofs to the metal structure. The relative movement of the large adherents, caused by temperature changes, must be absorbed permanently, and this requires a corresponding thickness of the adhesive layer. As a rule of thumb, the thickness should approximately correspond to the length difference expected to occur between the adherents. For example, in the case of a bus roof with a length of 10 m (GRP on steel) and a temperature of 80 ° C at solar radiant exposure, the bond-line should be at least 5 mm thick. The operational temperature may differ by approximately 60 K from the room temperature prevailing during the bonding process and, in some cases, it may even increase further.

Hem-Flange Bonding and Antiflutter Bonding For the bonding of doors and bonnets (hoods), the build-up of adhesion must not be impaired by any oil located on the adherents (generally 3-4 g m~2). If adhesives based on epoxy resins, butyl rubber and PVC plastisol are used, or combinations of PVCwith rubber, or acrylate-plastisols, the oil is absorbed by the adhesive during the curing process in the e-coat curing stove.

|

Figure 8.8 Hem-flange bonding. |

If a high-modulus, high-strength adhesive is used for bonding the sheets to be joined in the hem area, the rigidity of the doors and the hoods is increased considerably (Figure 8.8). Protection against corrosion is improved by the sealing effect of the adhesive, with epoxy adhesives showing the best performance. The greatest protection against corrosion is achieved, however, by means of additional fine seam sealing.

When add-on components of the mostly complex structures are joined, and stiffening profiles for the hoods and roof are glued on, the bonding site is expected to damp vibrations while producing a stiffening effect, but without being outlined against the outer sheet. As the components pass through different cleaning and painting baths, and are heated to high temperatures (mostly up to 180 ° C) in the e-coat curing stove [11] where they cure and cool down to ambient temperatures, very efficient adhesives are required for this purpose (e. g. PVC plastisols). Rubber adhesives are also being used increasingly for this purpose.

Large gap widths may be bridged by means of products which foam in the stove and prevent further outlining.

Bonding of Plastic Parts In lightweight vehicle construction, use is increasingly being made ofplastic materials owing to their low material density on the one hand, and to the relatively easy fashioning of complex shapes on the other hand. Compared to metals, their strengths and moduli are considerably lower, with the exception of carbon fiber-reinforced plastics that are not taken into consideration here. Surface-to — surface joining by bonding is the first-choice joining technique rather than point-like joints with high local tensions.

For the joining of material combinations, bonding is also superior to other joining techniques in many cases, for example, when a plastic fender is joined to a metal structure, when a polycarbonate (PC) roof part is fixed or a PC side window, when a GRP bus roof is fixed, or when plastic rear gates including the glass pane are joined in combination.

No outlining is tolerated, either, in the case of visible vehicle parts that must be repainted, and the mechanical properties of the adhesive and the joint must not be impaired during the painting process, where temperatures of about 150 °C will be encountered.

As some of the plastic materials used (e. g. polypropylene) are nonpolar and have a low surface energy, adhesion promoters are often applied, or a physico-chemical preparation of the adherents is performed before the bonding process takes place (corona, low-pressure plasma, plasma surface treatment at atmospheric pressure, fluorination, pickling, etc.). Today, special acrylate adhesives are emerging onto the

market that may build up adhesion on almost every type of plastic material by means of a graft reaction, while not requiring any labor-intensive surface preparation. Although no long-term results are yet available, this trend shows great promise.

The most frequently used adhesives, however, are polyurethanes, with preference given to two-part systems. Their strength builds up very rapidly, and independently of the ambient moisture. A wide variety of PU systems is available, ranging from soft, low-strength systems to high-strength, high-rigidity adhesives.

It must be noted that the Tg of the adhesives must not to be within the range of the intended operational temperature, because slight changes in temperature would otherwise considerably modify their modulus and strength, and the properties of the component would be largely temperature-dependent.

Structural Bonding of Bodies In the field of vehicle body construction, structural bonding is defined as the creation of a rigid long-life and force-transmitting joint of rigid high-strength adherents by means of an adhesive, even in areas which are exposed to the risk of a crash. ‘Long-life’ means during the entire service life of the vehicle, while ‘rigidity’ means moduli of elasticity in an order of magnitude of 103 MPa with regard to the adhesive, and 105 MPa with regard to the adherents.

These values make structural bonding considerably different from direct glazing and the majority of all other bonded joints created in vehicle construction. Structural bonding makes it possible to increase the rigidity of the components and the crash resistance, both of which are physico-mechanical properties. In general, the materials joined by means of bonding are metals, for example different types of steel, aluminum and magnesium.

One important aspect that helps us to understand the high performance of structural bonds is the Tg, or rather the range of Tg-values of the adhesive. The Tg should not be in the operational temperature range of the bonded body parts (i. e. —30 °Cto +80 °C). Rather, the Tg should be > 80 °C, thus ensuring both rigidity and crash resistance. As a consequence, the operating temperature should be <Tg. For the purpose of direct glazing, as described above, the glass temperature and the operating temperature must be chosen in reverse sequence. For direct glazing, the Tg must be below the operating temperature. With regards to polymer chemistry, adhesives are formulated so as to contain different components that induce a toughened rather than a glass-like brittle condition below the Tg. This is the main difference compared to rigid epoxy adhesives, which are not resistant to crash and therefore may not be used for structural bonding according to the above-mentioned definition.

High-strength adhesives suitable for different industrial applications have been known for a long time. However, for the structural bonding of bodies — which requires a high rigidity and high-energy storage capacity in the case of a crash — the brittleness of the adhesives in the case of an impact load, enhanced by lower temperatures, was opposed to these requirements. Although the properties of the adhesives were improved by developing so-called ‘rubber — toughened epoxies’, the scope of the improvement was not sufficiently important. The ultimate success was achieved by the development of a new method of toughness modification, involving an elastic component which is incorporated into the epoxy matrix like an island or by a

reactive approach, and which makes it impact-resistant. Now, the deformability of the still rigid high-strength adhesive is high enough to prevent failure due to glass-like brittleness, in the case of stretching the adherent beyond the tensile yield point induced by the application of a load. It is important to ensure deformability of the adhesive even at lower temperatures, and the whole operating temperature range must be covered with regards to this safety-relevant issue. In the case of a crash, the stretching of the metal absorbs the most important part of the energy, while the contribution of the adhesive itself is only of secondary importance. On the other hand, however, the high-strength surface-to-surface adhesive joint is essential to allow the metal to store energy to the desired extent. Point-like joints (e. g. welding spots) will fail at less important deformations and local tensions, resulting in a lower energy storage. This principle helps to explain why steel and aluminum are — and will continue to be — the preferred materials for body structures exposed to the risk of a crash. Magnesium is less suitable for this purpose due to its brittleness, which is inherent to its hexagonal lattice structure. At the same time, this principle of action provides important indications for the structural design of the joint. The load-bearing capacity of the joint, resulting from the bonding area and the adhesive strength, is required to be at least slightly higher than the forces required to stretch the adherents.

The cross-sections of the adherents, resulting from their thickness, are required to correspond to the areas of the bonded surfaces. If, for example, the bonding areas of thick adherents are too small, they may not stretch to the extent required for energy storage, as the joint will already have failed.

With regards to energy storage in the case of a crash, structural bonding is compatible with modern high-strength steel. With an increase in deformation speed, the strengths of both the adhesive and the steel adherent increase, albeit to different extents. High-strength steel, however, has softer dynamic deformation characteristics than ‘normal-strength’ steel; that is, with increasing impact speeds both types of steel will behave more and more alike. At a speed similar to real crash speed, their deformation characteristics are almost at the same level. In other words, high-strength steel has a high deformation stability in the case of an impact occurring at a lower speed. In this case, the adhesive is not exposed to any severe deformation, because the steel adherents are not stretched at all, or only to a very slight degree. In the case of higher impact speeds, however, high-strength steel will behave like softer steel. In any case, when joining high-strength steel adherents, the engineer must adjust their thickness to the relevant parameters, using thin-walled material that will save weight.

For structural joining purposes in vehicle construction, bonding competes with a variety of other joining techniques, including welding, riveting, clinching, joining by screws and soldering. In order to decide whether a technique is suited for a special purpose, it is important to know how it contributes to the fulfillment of present-day requirements in vehicle manufacture. These are mainly:

• suitability for multimaterial applications

• increased body stiffness

• increased operational strength

• increased energy storage in the case of a crash

• less corrosion

• increased comfort (acoustics)

• increased speed of application/processing

• functional cost savings

For nearly all requirements, bonding proves to be equal or superior to the other joining techniques, especially with its new generation of epoxy resins. The only disadvantage is that, immediately after assembling, there is no strength, as the strength will build up only during the course of the curing process. Consequently, hybrid bonding is increasingly being used, for example the combination of spot welding with bonding [12]. A comparison of joining techniques is provided in Table 8.1.

The number ofwelding spots may be considerably reduced, which will help reduce costs. In body construction, hybrid bonding is sometimes performed — that is, bonding in combination with other joining techniques (e. g. self-punching riveting) — especially when aluminum is used. The adhesive surface-to surface joint contributes to crash resistance and rigidity, while the aluminum saves weight. This technology has recently made it possible to produce a superclass vehicle with an aluminum body weighing 40% less than predecessor models, yet with an increase in rigidity of 60%.

In 1998, the new generation of high-strength adhesives with crash-resistanceimproving properties was used for the first time in models with higher production quantities.

Calculation methods, especially for the behavior of adhesives in the case of a crash, are under intense scrutiny even today. Whilst the number of welding spots has already been reduced, this development is still at an early stage. In an experiment performed on a real body with 4000 welding spots, the torsion resistance was measured, followed by a hybrid bonding carried out on the same body (bonding plus spot welding). As a result of using bonded joints, the rigidity was increased by approximately 40%. When the experiment was repeated with a body in which the number of welding spots was reduced from 4000 to 2000, within the range of common tolerance the rigidity of the bonded spot-welded body was unchanged, showing that the potential of this method had not yet been reached.

Several years of experience, also with regards to dynamic operating strength, and gathered with millions of structurally bonded vehicles, have shown that there is a

|

Table 8.1 Comparison of joining techniques. a)

a)Grading indicated as: + + +, very good; + +, good; +, fair; 0, poor. |

|

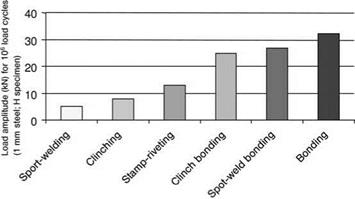

Figure 8.9 The fatigue properties of different joints. |

considerable cost-saving potential here. For example, in a new vehicle, the rigidity of a bonded spot-welded body is about 20% higher than in its nonbonded counterpart, and this margin, which is important for both safety and comfort, will surely grow wider after several years of operation. The rigidity of a conventional body will decrease by around 20%, while that of a bonded version will decrease by only 5%; moreover, at that time the torsion resistance of the bonded structure will be 40% higher. Clearly, the absolute percentage changes obtained will depend on the model of the vehicle. These findings confirm the first indications provided by experiments investigating the dynamic fatigue limits of different joining techniques. The fatigue properties of different types of joints are shown in Figure 8.9.

In addition to the cost-saving potential, a reduction in the number of welding spots will further increase the joint’s performance, since every spot avoided will reduce the thermally induced changes in the structure of the metal (this is also apparent in Figure 8.9). Another aspect to be taken into account is the enhancement of processing speed. Each spot requires around 3 s for both spot-welding and clinching, and almost twice that time for self-punching riveting. By comparison, the spray application of a suitable adhesive requires only 2 s per meter of bond-line. Even tacking by means of remote laser welding (which is still under discussion at present) requires 0.5 s per tacking point.

Bonding Process In body-in-white construction, the adhesive is applied onto the oiled sheets using robots. The application temperature is slightly elevated to around 50 °C, which induces a decrease in viscosity. Although on cooling the viscosity increases again. Adhesives with a high yield point are particularly well suited, because this improves rope stability and resistance to being washed away. At the same time, the viscosity must be as low as possible in order to facilitate ‘pumpability’. Depending on the product, the adhesives can be applied by means of beads, swirl application or spray application.

In order to prevent pollution of the e-coat bath during subsequent cleaning and painting processes, it is advisable that pre-curing/pre-gelation be performed by

means of heat application (e. g. induction heat), or preferably in a special body-inwhite stove at 110-120 °C that may also be used for other products.

The final curing takes place in the e-coat stove at temperatures around 180 °C, with an adequate curing window between 150 °C and 200 °C, and curing times (e. g. 30 min) with similar tolerances. In future, crash-resistant cold-setting adhesives may replace crash-resistant hot-setting adhesives, at least partly, in order to dispense with the body-in-white stoves, or in order to join finished painted components to form the body.

These adhesives have a tensile loading shear stress of (sometimes considerably) more than 25 MPa, while the tensile strength ofthe adhesive film is even higher. The stretch at break is slightly above 10%. Formerly, rigid but glass-like brittle products had much lower values (of only few per cent).

Test Methods (see Section 7.2) Nearly all test methods generally employed for adhesive joints and adhesives are used here. As the adhesive joints must be high — performing with regards to the service life and the climatic conditions to which a vehicle is exposed, different accelerated aging tests are carried out in particular. Beyond the well-known test methods, a ‘crash peel resistance test’ is performed that takes into account the high rates of stress occurring in the case of a crash. For this purpose, the crash peel resistance is generally tested according to ISO 11343. A wedge is driven at high speed (several m s-1) into a suitable test specimen, and the peel forces related to the bonding width are evaluated. The testing is performed at temperatures that are relevant for vehicles and allow the crash peel resistance to be determined in N mm-1, as well as a quantitative value for the energy consumed. The method is well suited for early identification of the different ‘crash suitabilities’ of adhesives in laboratory experiments (Figure 8.10; also see Section 7.2.5).

In addition, double hat boxes are shock-loaded in falling towers in order to determine the deformation behavior, similar to the conditions encountered in real components. Heights of fall of around 4-10 m are used to create a speed that imitates a crash situation; changing the weight may modify the energy of fall.

Quality Assurance The safety-relevant function of bonded joints exposed to the risk of a crash requires suitable measures of quality assurance. No nondestructive testing studies are carried out on a bonded body, and if a bonding defect is discovered it cannot be simply repaired; hence, quality assurance is more important than quality control. Visual inspection systems, robotic application and automatic dosage control ensure the application of the correct quantity of the correct adhesive, without interruption, at the correct location. According to the required performance, different structural adhesives will be used in a vehicle body, and these are commonly given different colors in order to identify them (the colors are of no importance with regards to their functions).

The viscosity of an adhesive is exponentially increased by an increase in the length of its polymer or prepolymer chains. The easy pumpability of an adhesive indicates that the storage life has not been exceeded, or that undue aging has not taken place as a consequence of elevated storage temperatures.

|

The recommendation is to work with a bond-line thickness of approximately 0.2 mm, although the adhesives are rather tolerant in this respect. Most adhesives may be formulated to slightly foam in order to ensure proper filling of the gap. In order to take into account of the tolerances in gap width, however, it is common practice to work with a surplus of adhesive.

Environment Protection and Hygiene of the Work Place With the new generation of adhesives, the measures to be taken do not differ qualitatively from those already applied when working with epoxide adhesives for the purpose ofnon-crash-resistant stiffening bonding, which have already been used for a long time. The usual measures to be taken for the hygiene in the work place remain unchanged. It is advantageous to apply the adhesive by automatic methods only. When bonding is combined with thermal joining techniques (resistance spot-welding, possibly laser welding tacking in the future), the emission of volatile pyrolysates induced by the adhesive is considerably less important than that induced by the corrosion protection oils and forming oils. When the number of welding spots is further reduced, the total emission at the work place will be reduced even further.

At the end of its service life, the vehicle is shredded and the steel pellets are recycled in the electric furnace. Minor amounts of adhesive residues still adhering to the surfaces do not represent any problem.

Although some attempts have been made to develop a method for simple, controlled debonding, this has not yet been successful. Moreover, as for most of the time hybrid bonding techniques are used, a simple detachment of the welded, riveted or clinched body parts is barely possible.

Structural bonding is the driving force of modern lightweight body construction that will also reduce fuel consumption. During past decades, the typical weight of a passenger car of the same type has increased considerably; for a lower mid-size compact car produced at high production quantities the weight has increased from 750 kg (in 1980) to 1200 kg (in 2004). Experience teaches us that 1kg of automobile structural adhesive has a weight reduction potential of around 20 kg, which in turn may reduce fuel consumption by 601 for a total traveled distance of 150 000 km — equivalent to a decrease in carbon dioxide discharge of 150 kg.

Bodywork Repairs The high curing temperatures required by one-part epoxy adhesives can only be created in the e-coat stove, and not in the repair shop. Therefore, for repair purposes, new two-part epoxy adhesives are used that have an acceptable crash resistance but have an inferior performance compared to OEM systems. These are contained in suitable cartridges and mixed using static mixers. Curing takes place at room temperature and may be accelerated by using a repair paint oven, generally with temperatures of 60-80 °C. The parts to be bonded must be cleaned and free from oil before the adhesive is applied, as the epoxy systems are only capable of absorbing oil at higher temperatures. An alternative for repairing limited areas is to use a standard joining technique such as spot welding, with the welding spots set closer to each other.

8.2.3

8 ноября, 2015

8 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике