7.1.1

Stress-Strain Analysis of Bulk Specimens

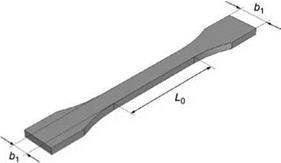

Tension tests are performed on dog-bone-shaped test specimens (Figure 7.1). This geometry provides for a uniform stress and strain distribution in the central gauge section, where these values are at a maximum. Thus, the specimen extends and fails under well-defined conditions. Some flexible adhesives will sustain large extensions up to several hundred percent prior to failure, and this will place limitations on the sample geometry in order to obtain a failure within the travel range of the tensile

|

Figure 7.1 The basic geometry of a ‘dog-bone’-shaped bulk tensile specimen. |

testing machine. According to the standard ISO 3167 a multipurpose test specimen with a minimum length of 150 mm and a gauge width-to-gripped width ratio of 1: 2 is recommended for structural adhesives. Smaller test specimens may be more appropriate for flexible adhesives, while the plastics tensile standard allows for a half-sized test-piece. The rubber test standards specify a sample with a smaller gauge width-to-gripped width ratio. Although, there is no general preference as to which type of specimen is to be tested, it should be noted that test results obtained from different geometries might not be identical.

7.1.2

13 октября, 2015

13 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике