Laminated red maple beams were used as the mandrel to apply the Epoxy FRP over the wood by filament winding (Fig. 4). Delamination samples both with HMR and RF coupling agents were cut from the epoxy FRP-wood beams, and the final dimensions of the

|

Specimen |

Coupling agent |

No. of samples |

Bondline |

Average delamination (%) |

|

Wood-wood |

Without HMR |

6 |

Wood-wood |

3.20 |

|

FRP-wood |

With HMR |

12 |

FRP-wood |

3.21 |

|

With HMR |

12 |

Wood-wood |

8.90 |

|

|

Without HMR |

12 |

FRP-wood |

2.25 |

|

|

Without HMR |

12 |

Wood-wood |

0.74 |

|

|

Pressure p = 1.448 MPa (210 psi); open/closed assembly time t = |

3/50 min. |

|

Table 2 Delamination of Bonded Interfaces with RF Adhesive |

||||

|

Specimen |

Coupling agent |

No. of samples |

Bondline |

Average delamination (%) |

|

Wood-wood |

Without HMR |

6 |

Wood-wood |

4.00 |

|

FRP-wood |

With HMR |

12 |

FRP-wood |

0.00 |

|

With HMR |

12 |

Wood-wood |

6.53 |

|

|

Without HMR |

12 |

FRP-wood |

2.44 |

|

|

Without HMR |

12 |

Wood-wood |

1.46 |

|

Pressure: p = 1.241 MPa (180 psi); Open/Closed Assembly Time: t = 5/30 min. |

|

Table 3 Delamination of Phenolic FRP-Wood Bondline under Different Pressure Conditions (with RF Adhesive and without HMR Primer) Average delamination (%) Open/closed

|

|

Table 4 Delamination of Phenolic FRP-Wood Bondline under Different Assembly Times (with RF Adhesive and without HMR Primer)

|

|

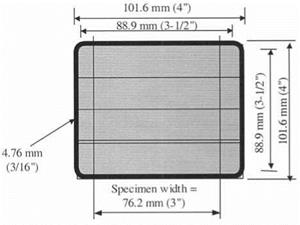

Figure 4 Fabrication of epoxy FRP-wood sample by filament winding process. |

Table 5 Delamination of Epoxy FRP-Wood Laminated Samples with RF or HMR Coupling Agent

|

Average delamination (%) RF (6 samples) HMR (6 samples)

|

samples were 76.2mm x 76.2mm x 111.1mm (3" x 3" x 4|"). The epoxy FRP-wood interface bond performance under exterior or wet-use exposure conditions (three wet — dry cycles) was evaluated to study the effect of coupling agents (primers) to promote bonding. The epoxy FRP-wood interface bond was generated during the filament winding process; therefore, the open/closed assembly time and clamping pressure along the epoxy FRP-wood interface could not be controlled. The influence of two different coupling agents on bond performance [4] was investigated. The epoxy FRP-wood interface with HMR coupling agent performed well under cyclic wetting and drying delamination tests (no delamination); whereas, the interface with RF coupling agent failed to pass the delamination test (44.2% delamination after the third cycle) (see Table 5) [4]. Thus, it is recommended that the HMR coupling agent be applied to the red maple wood surface before wrapping with the epoxy FRP reinforcement, since the HMR significantly improved the bond integrity and durability of the epoxy FRP-wood interface.

14 июля, 2015

14 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике