Structural joints are purposely not designed with the fibers intersecting the plane of the bondline as a result of the weakness of this design. However, this relationship can be of

|

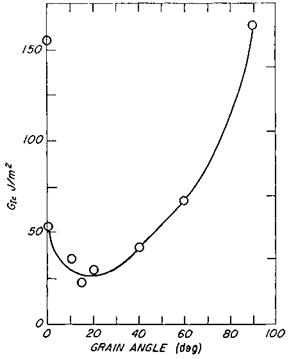

Figure 14 Effect of adherend grain angle to the bondline on the fracture toughness of bonded wood joints in cleavage. (From Ref. 3.) |

great importance in the delamination of structural joints, where there are unavoidable local grain deviations, such as around knots. Furniture and picture frames often contain mitered joints in which the fibers intersect. However, the joints are often pinned or doweled for added strength.

Generally, fracture toughness increases with increasing grain angle, although there is usually a minimum toughness between about 10 and 30° (Fig. 14) [3,16,30]. The shape of the relationship varies from almost flat to very steep as a function of species and the type of adhesive. There is usually a minimum in the range 15 to 30° above the bondline and a maximum at 90°. Both the stress intensity factor (K1c) and the strain-energy release rate (G1c) follow the same trend [30]. The basis for the shape of this relationship is unclear. Ruedy and Johnson speculate that it is due to variation of adhesive penetration and stored energy at the crack tip with grain angle, while Ebewele and others [3] think the relationship is caused by variation of the Cook-Gordon ‘‘weak-interface’’ crack-stopping mechanism with grain angle [58]. White [33] attributed the increased toughness at large grain angle to increased penetration and reinforcement of the interphase. The depth of penetration of loblolly pine (Pinus taeda) by a resorcinol adhesive increased nine times and the fracture toughness doubled as the grain angle was increased from 0 to 45°.

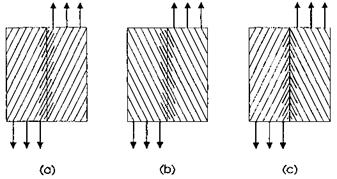

A grain angle effect has also been reported in the shear strength of bonded joints. When the grain direction runs with the applied force (Fig. 15a), the principal stress across the grain direction is in compression (closing mode). When the grain direction runs against the applied force (Fig. 15b), the principal stress across the grain is in tension (opening mode). The shear strength of the joint is highest when the grain direction runs with the

|

Figure 15 Schematic of joints with nonplanar grain orientations: (a) both adherends in compression (closing) mode perpendicular to the grain; (b) both adherends in tension (opening) mode perpendicular to the grain; (c) one adherend in each mode. Grain direction indicated by fine lines. Adhesive penetration indicated by heavy lines. |

applied force. This effect is due to the disparity between the tensile and compression strengths of the wood and to adhesive penetration. When the grain direction is not parallel to the surface, the adhesive is very likely to penetrate the wood deeply. When such a joint is loaded in the opening mode, the strength of the cell wall, particularly the S1 layer and the S1-S2 interphase, is still the limiting factor. Adhesive penetration adds little to the tensile strength of wood perpendicular to the grain. However, in the closing mode, plugs of adhesive in the cell lumens increase the compression strength across the grain. They also distribute the shear force away from the plane of the joint. This was evident in the results of Furuno and others [43], who used tensile single lap joints for their experiments. Joints loaded in the closing mode were 25% stronger than parallel-grain joints and 45% stronger than joints loaded in the opening mode. Fracture of a joint with one adherend in the opening mode and one in the closing mode (Fig. 15c) occurred at low strength as a result of the opening mode. Swietliczny [59] conducted a similar experiment using compression block shear specimens and found the opposite results. The difference can be attributed to the method of loading, particularly the support of the specimen during loading, which inhibited opening or tensile fracture.

12 июля, 2015

12 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике