Spalling of the surface layers of concrete in reinforced members may occur as a result of reinforcement corrosion (Fig. 6.1), the effects of fire or due to impact. Where the spalling is local and the cover is more than 25-30 mm, conventional sand-cement mortars based on high quality sands and applied using good rendering practice may be used. However, great care in surface preparation is necessary to ensure adequate adhesion.

For local spalling where the cover is between 12 and 25-30 mm, polymer modified cementitious materials are more appropriate. The polymers are usually supplied as very fine polymer particles dispersed

|

Fig. 6.1. Spalling of concrete in reinforced members. |

in water to form a stable white milky emulsion or latex. In some cases, however, the polymer can be supplied in fine particulate form. The polymer modification of the mortar can be beneficial for the following reasons:

(1) it acts as a water-reducing agent;

(2) it improves bond to the concrete substrate;

(3) it improves flexural and tensile strength;

(4) it reduces permeability to water and carbon dioxide;

(5) it acts to some extent as an integral curing aid.

Polymer types include (refer to Chapter 2 for further details):

Polyvinyl acetate (PVA) — not recommended in external applications or under wet service conditions.

Polyvinyl dichloride (PVDC) — not recommended for use with reinforced concrete because of the danger of chloride release. Styrene butadiene rubber (SBR) — suitable for most circumstances. Acrylics and modified acrylics — suitable for most circumstances.

A typical repair mortar composition might comprise:

|

|

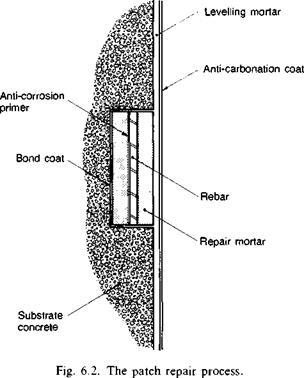

To improve adhesion to the prepared concrete surface, bond coats comprising a polymer latex and cement mixed to a slurry may be applied. However, the mortar must then be trowelled in place whilst the bond coat is still tacky or adhesion problems at the bond coat/mortar interface may develop with time. Epoxy resin bond coats are often used on the reinforcement following cleaning using gritblasting or water jetting. The epoxy may be lightly dashed with sharp sand to improve the mechanical key with the subsequently applied mortar. Some resin bonding aids are formulated to receive the cementitious repair before the resin cures. Fig. 6.2 illustrates schematically a typical preparation procedure and the process of patch repair of spalled concrete.

For the repair of shallow spalls or where the cover to the steel is less than 12 mm repair mortars based on reactive thermosetting resin binders may be more appropriate. Their advantages include:

(1) Development of high mechanical strength within 24-48 hours.

(2) Encapsulation of the reinforcement steel within a low permeability barrier which has excellent adhesion to both the reinforcement and concrete substrate.

(3) The possibility of formulation with lightweight fillers to produce low density thixotropic mortars which assist in repairs on vertical and overhead surfaces.

Resin types include (refer to Chapter 2 for further details):

Epoxies — formulated with specially graded dry fillers. Correct proportioning and mixing are vital to achieve optimum properties. Because of the exothermic reaction thermal contraction on cooling may cause interfacial stresses to be built up. However, with epoxies the maximum heat evolution occurs whilst the resin is in a fluid state. With careful formulation and correct mixing and application the heat output can be controlled and shrinkage becomes negligible.

|

|

As has been mentioned in Chapter 2 the rate of curing of epoxy systems is temperature dependent and thus it is important to select a formulation appropriate to the ambient temperature during application. At 20 °С most epoxies develop 80% of their ultimate properties within 24-48 hours.

Unsaturated polyesters — proportioning and mixing is less critical than with epoxies. Again, curing is an exothermic reaction but the maximum heat evolution occurs after the resin has set. This can result in significant thermal contraction inducing high stresses and maybe debonding at the interface with the substrate concrete. In addition the volume of the hardened polymer is less than that of the freshly mixed adhesive. For these reasons polyester mortars are only applicable for small volume repairs but they have the advantage of being able to cure at lower temperatures than epoxies and thus may be used overnight for load application the next day.

Acrylics (methyl methacrylates) — tend to be formulated such that they exhibit less shrinkage than conventional polyesters. However, they have low flash points and are therefore highly inflammable in their pure resin state.

Many resin-based materials have a relatively low glass transition temperature and will lose a significant proportion of their strength and stiffness at this temperature. For the repair of fire damage internally within a building it is recommended that resin repairs are only used when either:

(1) Performance data demonstrates adequate fire resistance such that the material retains its structural properties under future envisaged fire conditions; or

(2) The material is adequately protected from fire by other materials and retains its structural properties at the expected fire temperature at the relevant depth within the section; or

(3) Loss of strength of other properties will not cause an unacceptable loss of structural section or fire resistance.

With resin-based repair mortars the reinforcement bars should be gritblasted and the system applied within four hours. Otherwise a non zinc-rich holding primer may be considered. Rust converters should be treated with caution since some containing phosphoric acid can inhibit cure of the subsequently applied resin. The top coat of any compatible primer or bond coat applied to the substrate concrete or steel bars should still be tacky when the repair mortar is applied.

24 августа, 2015

24 августа, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике