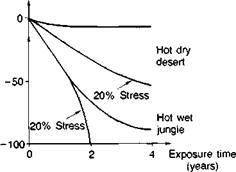

The durability of joints, and particularly structural adhesive joints, is generally more important than their initial strength. It has been found that the mechanical properties of a bonded joint may deteriorate upon exposure to its service environment and, further, that an interfacial locus of failure may often be found only after environmental attack. A number of empirical laboratory investigations reported in the literature many years ago established that water, in liquid or vapour form, is the most hostile environment for structural adhesive joints that is commonly encountered. The key factors affecting bond durability in general have been distilled from the literature(37, 69, 89-91), and Kinloch(69) brings together the most useful international contributions of adhesive scientists and technologists. The extent of the potential problem is illustrated in Figs. 3.1 and 4.20.

The problem with bonded joints is that most of the load is transmitted through the edge zones, and it is these which come under environmental attack first. In fact, the load becomes progressively borne by the inner region of the joint but, nevertheless,

|

Loss in double lap shear strength (%)

Fig. 4.20. Effect of outdoor weathering on joint strengths (Refs. 92, 93). Adhesive: epoxy polyamide film. Adherends: aluminium alloy. Pretreatment: Chromic-sulphuric acid etch. Cure temperature: 175 °С. |

it is still the most highly stressed regions which are under the greatest environmental attack. It will be appreciated that the mechanical response of bonded joints is complex, so that the interpretation of the behaviour of environmentally exposed joints becomes even more onerous. For instance, the measured residual joint strength is a function of change both in the resin cohesive properties, and in the adhesion between adherend and adhesive. Thus joint durability demands at least a two-fold consideration of (a) the structural integrity of the cured adhesive, and (b) the environmental stability of the interface.

In so far as fracture loads are related to stress concentrations at the ends of a joint, then if the bonded area is sufficient to enable stress redistributions within the adhesive layer, changes in adhesive or cohesive properties will not compromise the integrity of bonded joints of an appropriate geometrical configuration. Heat alone is likely to be beneficial in post-curing the adhesive. The diffusion of moisture into the bondline may or may not be beneficial. The combined effect of heat and moisture however is likely to be detrimental, and the synergistic effects of heat, moisture and stress will certainly be detrimental. Some general observations on joint durability are summarised in Table 4.5, aspects of which are expanded in the following dialogue. It will become apparent that the environmental performance of bonded joints depends more on adhesive/substrate interfacial behaviour than on cohesive adhesive layer behaviour.

6 августа, 2015

6 августа, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике