Surface preparation should include (a) removal of all loose and unsound material until coarse aggregate is exposed (b) cleaning and (c) drying (although there exist some special polymeric systems which are claimed to bond to damp or wet concrete, and cementitious

|

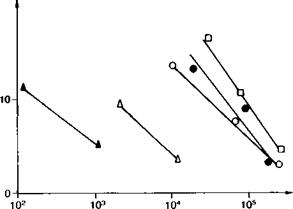

Applied stress (N/mm2)

|

Log Failure Time (min)

□ Phosphoric acid anodise (Boeing process)

• Chromic acid anodise

0 Chromic-sulphuric acid etch й Sulphuric acid anodise

1 Vapour degrease

Fig. 3.11. Applied stress versus failure time for nitrile-epoxy/aluminium — alloy joints exposed to 100% r. h. and 52 °С (Ref. 58).

or polymer-modified cementitious systems must be used against a dampened surface). Practical problems are likely because of the scale and/or inaccessibility of the works. The importance of cutting back the concrete to a clean sound surface cannot be overemphasised since adhesion relies partly on mechanical interlock by penetration of the surface pores (see Fig. 3.12), and partly on the physical forces of attraction to clean high energy aggregate surfaces. The comments pertinent to metal oxides apply equally to the hydrated surface oxide layers formed on siliceous materials. There exist several useful publications detailing practical procedures and recommendations(33,60-66), whilst Hewlett(67) gives some detailed consideration to the physical and chemical surface nature of concrete.

|

All loose and unsound concrete particles and hardened laitance must be removed, preferably by mechanical means. Subsequent methods for preparation include sand-blasting, bush hammering with blunt tools, needle gun treatment, wire-brushing, water or steam jet cleaning, vacuum blasting and burning off. Chemical etching, with a 10-15% solution of hydrochloric acid, should be used only with previous water saturation of the pore system, to prevent deep penetration of the acid, and the surface should be flushed with water whenever the effervescence ceases. This procedure should be repeated until the surface exhibits a satisfactory texture, but the process is not without its problems. Shields(29) further advises rinsing with water solutions of 1% w/w ammonia, or 10% w/w sodium bicarbonate, to neutralise the acid. Abrasive blasting, too, is not without its drawbacks; aggressive abrasion results in numerous blowholes which may have to be filled prior to coating with adhesive. Cleaning of the substrate surface should follow this removal of the unsound layers. Typical contaminants include grit, dust, oil and greases, and these are best removed by water-blasting, steamcleaning in conjunction with a suitable detergent, or vigorous scrubbing with a detergent solution or chemical cleaner. Care must be taken not simply to redistribute surface oils and greases.

Finally, the surface must be dried as much as possible, preferably leaving a surface water content of less than 4%. Rough checks might be carried out by holding absorbent paper against the surface, or by taping a polythene sheet to part of the surface and watching for condensation on the underside. Gaul(64) suggests that if this is done under the same ambient conditions and for the same duration as the applied polymer takes to cure, effective bonding may be anticipated if condensation is not observed. The application of penetrating sealers and primers to the substrate may provide the

best solution to the creation of a sound and stable surface for bonding(67).

Little information exists on the effects of surface pretreatment on bond strength and durability, and there is a general absence of appropriate test methods to assess such effects on adhesion. The pull-off test(68) is, perhaps, currently the most suitable; the slant — shear test, as described in BS 6319(69), is of limited use in assessing adhesion because the interfaces are not subjected to tensile forces.

22 июля, 2015

22 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике