Adhesives have been employed in the automotive industry since its earliest beginnings, with the use of natural resins to bond wood and fabric bodies. With the advent of the all-steel monocoque adhesives disappeared from the body, although they continued to be used for interior trim applications and are still used in this role today. The early metal-to-metal adhesives represented an extension of the low strength gap-filling interweld sealers and contributed little, if anything, to the overall strength of the assembly. However recent developments in synthetic resin technology have resulted in a very wide range of adhesive materials available to the design engineer, ranging from weak low modulus ones to tough high strength formulations. Adhesives are now designed into vehicles at the concept stage, and will be used increasingly in demanding roles as design philosophies, and the materials from which vehicles are constructed, evolve.

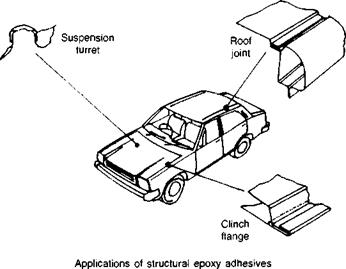

Early metal applications in car body manufacture were concerned with the bonding of stiffeners to bonnet and boot lids in order to overcome problems of flutter and rattle at high speed. These components, together with flange seams and clinched seams in door and roof assemblies, remain popular candidates for adhesive bonding (Fig. 1.10). The adhesives are generally applied to steel contaminated with mill oils at the body-in-white stage, and a number of tack welds may additionally be used to hold the assembly in place. The use of robotic automatic dispensing equipment has enabled a consistent application quality to be achieved for mass production, although careful controls are necessary to monitor the process and the materials used.

Adhesives are used in many other applications on vehicles, from attaching trim, for thread-locking, for gasketing in the engine, and for components such as headlamps, radiators and brake linings. The use of polyurethane adhesive-bonded direct glazing for the front, rear and side screens of cars is now a well established technique, contributing to both a flush aerodynamic exterior as well as enhanced body stiffness. One recent innovation has been developed by Peugeot in which a carbon fibre drive shaft is bonded into steel yokes at either end to pick up the transmission and drive. The carefully shaped co-axial joint design represents a development which has been used successfully in rally cars and latterly in standard production models by other French motor manufacturers.

The future use of adhesives in motor vehicle body shell construction depends significantly upon the materials used. Aluminium may compete with high strength low alloy steels, and reinforced plastics will increasingly be used in combination with other materials. The BL ECV3 concept vehicle was one demonstration of a lightweight vehicle comprising all three materials, in which very significant use of adhesive bonding was implemented. Currently many specialist vehicles are constructed with mixtures of materials, particularly plastics, in which large volumes of adhesives are used. At the same time mass-produced vehicles are increasingly being fabricated with coated steels for which joining by adhesive bonding is very attractive in order to minimise damage to the surface coating.

|

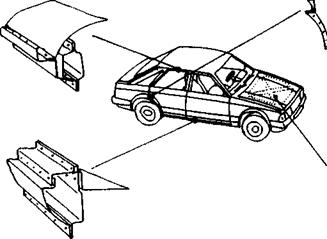

Adhesives are used extensively in the commercial vehicle sector, particularly for the joining of dissimilar materials. For instance, many truck cabs now comprise large amounts of reinforced plastic bonded steel. Container vehicles, refrigerated or otherwise, are often constructed from bonded sandwich panel assemblies; further, by making the bonded container act structurally much of the conventional chassis is unnecessary, so reducing weight or enabling a higher payload to be transported. An additional approach to reducing the structural chassis weight has been developed by Leyland-Daf in conjunction with British Alcan. The Ley land TX450 concept vehicle (Fig. 1.11) comprises an aluminium monocoque tubular chassis of great torsional stiffness. The hollow longitudinal members are formed from bonding three individual aluminium extrusions together, whilst the cross members also employ adhesive bonding. A weight saving of over 30 per cent has been realised when compared to a traditional steel ladder frame chassis. Naturally, careful provision for surface treatment of the aluminium for bonding has to be made, as is the case in the development of aluminiumbodied cars.

Vehicle repair techniques, overseen by the insurance industry, are also being developed for bonding sheet steel panels. Epoxides and polyurethanes are used, and the benefits of using adhesives include the need for access only to the outside surface of the repair area as well as overall cost and time savings. Crash and impact tests have confirmed the suitability of such repairs as well as highlighting, as with new build operations, the need for judicious use of tack welds or rivets.

2 июля, 2015

2 июля, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике