Adhesives are used in a civil engineering context, in the track, and for the construction of rolling stock. Taking these applications in order, heavily filled acrylic adhesives have been used to provide a longitudinal shear connection between adjacent precast concrete beams in bridge structures. Although in the final deck mechanical devices aid the adhesive, bonding alone has been relied on when lifting pairs of beams into place. Resin injection has also been extensively used for the repair of brick and masonry arch bridges subjected to damage from vibrational or mortar loss.

In the track itself adhesives have been used in conjunction with bolts in the fishplate connections of continuously welded track. The adhesive serves primarily as an insulator, although it must also contribute to the 70 tonne axial loads and the bending arising from 25 tonne axle loads which the joint has to resist. In paved track, rail cleats have been glued into the supporting concrete raft.

In rolling stock adhesives have not been used for primary structural connections, but there are many examples of their usage in substructures. Amongst these are:

(1) aluminium skin and honeycomb structures, bonded with heat — cured film adhesive, for the sliding doors of suburban coaches

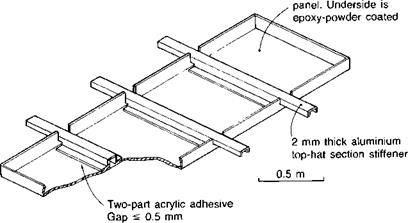

(2) attachment of top hat stiffeners to aluminium ceiling panels in inter-city coaches (Fig. 1.9)

(3) body side doors on the Class 58 locomotive are manufactured in zinc coated steel (IZ) and assembled using a two-part premixed acrylic

(4) manufacture of suburban multiple unit coach bodyside panels consisting of 2 mm thick IZ steel skins and top hat section stiffeners. Advantages over conventional spot welding are those of time savings and an improved surface finish

|

2 mm thick aluminium

Fig. 1.9. Bonded aluminium ceiling panels for British Rail’s Inter-City coaches. |

(5) toughened epoxies have been used to construct a GRP box structure with internal foam reinforcement for Mk III intercity coach doors.

In all of these applications the adhesive bond must remain sufficiently strong and stiff over the 20-40 year life of the rolling stock; the adhesive itself must also remain sufficiently flexible to allow joint deformation under impact loading. In these respects British Rail have favoured two-part acrylics, at least for use with zinc-coated steels.

2 июля, 2015

2 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике