This includes the finishing of buses, trams, lorries, rolling stock, trailers and coaches. The main performance requirements of this sector include:

• adhesion

• chemical resistance

• abrasion resistance

• durability

• high gloss

During their lifetime commercial vehicles are subjected to considerable stress through long running times and higher sustained speeds for greater distances. Coatings used in this market tend to follow trends in the vehicle refinish market. In recent years there has been an increased use of two pack acrylic polyurethane coatings which have replaced medium oil alkyds. The high gloss and exceptional durability of the acrylic topcoat result in enhanced appearance, reduced vehicle downtime for respraying and higher resale values. The coating also has increased resistance to fuels, lubricants, abrasion and

detergents, especially highly aggressive cleansing agents, reduced chalking, loss of gloss and surface scratching.

HIGH GLOSS GREEN PAINT FOR TRANSPORT FINISHES

|

Parti |

pbw |

|

Rutile titanium dioxide |

4.2 |

|

Vinamon GFW phthalocyanine green (ІСІ) |

4.2 |

|

Hydroxyl functional acrylic (c’ |

57.9 |

|

Baysilon OL17 (20%) |

0.51 |

|

Baysilon A (5%) |

0.21 |

|

Butyl acetate |

12.17 |

|

Methoxy propyl acetate |

4.06 |

|

Ethyl acetate |

1.35 |

|

Part II |

|

|

Desmodur N75 |

15.40 |

|

Total |

100.00 |

|

NOTEe. g. Synocure 867SD, 60% in 3:1 xylene:methoxy propyl acetate, 2.8% hydroxyl |

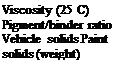

400 mPaS 0.18:1.0 50.9% 54.7%

400 mPaS 0.18:1.0 50.9% 54.7%

|

TABLE 5-5: PHYSICAL PROPERTIES OF HIGH GLOSS TRANSPORT FINISHES

|

Mix parts I and II. Thin to spray viscosity with 9:3:1 butyl acetate : methoxy propyl acetate : ethyl acetate and apply by conventional air spray. An aliphatic polyisocyanate is used to improve durability.

The types of resins used in commercial transport finishing include:

Macrynal SM510 Macrynal SM510n Synocure 867SD Synocure 865SD Setalux С1151XX51 Setalux C1153XS55 Desmophen A165 Desmophen A365 Desmophen A565

31 августа, 2015

31 августа, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике