Concrete and Terrazo surfaces may be sealed using solutions of high durability, thermoplastic acrylic polymers. The sealer helps to prevent the ingress of oil, grease, fats, acids and alkalis as well as reducing the tendency of the surface to dust or flake.

A sealer is produced simply by reducing a suitable acrylic to around 20% volume solids using an aromatic hydrocarbon solvent such as Shellsol® A (Shell) or Solvesso®100 (Esso). Single coats of these sealers do not offer sufficient protection to prevent carbonation of the concrete or chloride ion attack from road salt.

A. Availability

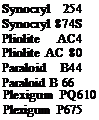

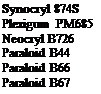

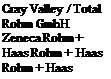

Thermoplastic acrylic resins are available from a number of suppliers, for example:

a) ![]()

|

|

|

|

Polar solvent soluble:

Plexigum PM685 Plexigum PM381 Plexigum PM708 Neocryl B726 Neocryl B831 Neocryl B875 Neocryl B880

b)  Aliphatic hydrocarbon solvent soluble:

Aliphatic hydrocarbon solvent soluble:

Pliolite VTAC Goodyear

Pliolite VTAC-L Goodyear

Pliolite AC3-H Goodyear

c) Low aromatic hydrocarbon solvent soluble:

Plioway EC1 Goodyear

Plioway ECL Goodyear

Plioway ECT Goodyear

Paraloid B67 (100%) Rohm + Haas

d) Low aromatic hydrocarbon solvent soluble:

Plioway EC1 Goodyear

Plioway ECL Goodyear

Plioway ECT Goodyear

e)

|

|

Commercial resins for use in concrete sealers include:

B. Future Trends for Thermoplastic Acrylics as Systems for Coatings for Cement Substrates

The future of thermoplastic acrylic resins in this market is limited due to the increasing focus on waterborne polymers and environmental regulations. Volatile organic compound (VOC) levels of below around 450 g/1 are not achievable at application viscosity with current thermoplastic acrylic resin technology. It is expected that there will be increasing substitution by water-borne products.

3 августа, 2015

3 августа, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике