Thermoplastic acrylics can be modified with a number of types of resins or plasticisers to suit a particular applications. Additives include:

• Nitrocellulose

• Solution vinyl resins

• Chlorinated rubber

• Chlorinated paraffins

• Ester plasticisers, e. g. dibutyl phthalate, dioctyl phthalate, dibutyl sebacate, Tricresyl phosphate.

• Non-oxidising alkyds

• CAB

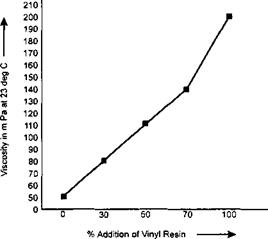

Due to the wide range of polarities exhibited by acrylics (dependent upon molecular weight and monomer composition), it is important to thoroughly check compatibility before deciding to use a particular resin. Solution vinyl resins impart adhesion and anticorrosive properties to the acrylic binder, but at the expense of application solids and film hardness. This is shown in Figure 3-1.

|

Figure 3-1 Addition of Vinyls to TPA’s |

2. Solvent Selection

Selecting a suitable solvent blend depends not only upon the method of application or end use, but also on the solubility parameters of the acrylic polymer. This, in turn, is governed by the monomer composition, molecular weight and molecular weight distribution of the polymer. Lower molecular weight polymers are more soluble and easier to handle, whilst higher molecular weight polymers enhance the performance characteristics of the coating.

In general, thermoplastic acrylic polymers have excellent solubility in esters and ketones; good solubility in aromatic hydrocarbons; and limited solubility in alcohols and aliphatic hydrocarbons.

Polymers based on short alkyl chain acrylate or methacrylate esters such as methyl methacrylate, and ethyl acrylate require stronger ester solvents or ester/aromatic hydrocarbon blends.

The longer alkyl side chain monomers such as butyl acrylate, butyl methacrylate and isobutyl methacrylate exhibit solubility in a wide range of solvents. The more polar acrylics have better organic solvent resistance, whilst the more hydrophobic acrylics give better water resistance.

Figure 3-2(1) shows the solubility of one such resin, Paraloid B67 produced by Rohm + Haas, in esters, alcohols, aromatic and aliphatic hydrocarbons. It can be seen that, depending on the solvent type, viscosities at a given solids content can vary by as much as a factor of 10.

iLi

BuOH BAcetate Xylene

IsoBuOH PMAcetate W. Spirit

Solvent Type ►

Figure 3-2

Effect of solvent on the viscosity of TPA

In formulating a paint or lacquer to meet a particular end use, it is invariably necessary to use a combination of solvents in order to meet application requirements, whilst at the same time, maximising cost effectiveness. It is therefore advisable for the formulator to consult the suppliers literature for information on the solubility characteristics of a particular resin.

27 июля, 2015

27 июля, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике