The surfactants (and colloids) control many of the properties of emulsion polymers and some knowledge of their nature and characteristics is a necessary pre-requisite for successful formulation of latex systems.

Any molecule containing a hydrophilic group chemically bound to a hydrophobic group can act as a surfactant. When a surfactant is dissolved in a water/oil mixture the individual molecules concentrate at the water/oil interface where the hydrophilic groups are in the water phase and the hydrophobic group is orientated towards the oil phase. The surface tension of the system is essentially that of the hydrophobic group. The concentration of individual surfactant molecules in water is limited, and at a relatively low concentration surfactant molecules will cluster together to form micelles. There is a critical concentration below which a surfactant will not form micelles. The minimum level required for micelle formation is known as the critical micelle concentration (CMC), and varies with surfactant type. The critical micelle concentration is an important characteristic of surfactants.

Surfactants are classified according to the ionic type of the hydrophilic group, being either anionic, cationic or nonionic. Most nonionic surfactants are made by reacting ethylene oxide with compounds containing an active hydrogen atom such as alcohols, carboxylic acids, phenols, amines or amides.

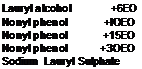

Chemically the majority of nonionic surfactants used in emulsion polymerised acrylics intended for surface coating applications are ethoxylated alkyl alcohols or alkyl phenols with an alkyl chain length of C8 or greater. It is convenient to represent a nonionic surfactant by the name of the alcohol (or other active hydrogen compound) and the number of molecules of ethylene oxide reacted with the alcohol, e. g. lauryl alcohol +4EO or nonyl phenol +15EO. It should be remembered that the ethylene oxide figure quoted is the average figure per molecule. The characteristics change with the degree of ethoxylation.

Low degrees of ethoxylation tend to render the surfactant oil soluble, whilst higher levels confer water solubility. The use of non-ionic surfactants may sometimes lead to the formation of small aggregates or “grainy” emulsions. This tendency is due to the weaker surface activity and the relative difficulty with which non-ionic surfactants form micelles. As a result of these deficiencies non-ionic/anionic surfactant mixtures are normally employed in emulsion polymerisation. The ionic component allows easy solubilising of the monomer whilst the non-ionic component confers emulsion polymer stability.

Ionic surfactants generally have a lower CMC than non-ionic surfactants. Ionic surfactants can be sub-divided into two types i) anionic and ii) cationic. Anionics are frequently used on their own or in conjunction with non-ionic types where their low CMC’s provide low particle size emulsions. However, their use has a tendency to induce foaming and enhance water sensitivity in the final coating. They can also give long term storage problems.

The simplest anionic surfactants are sodium and amine salts of fatty acids or rosin acids and these are used extensively for synthetic rubber emulsions. For the more stable emulsions required for surface coatings three main types of anionic surfactants are normally employed.

There are, half esters of sulphuric acid, half esters of phosphoric acid and sulphonic acid derivatives, where the sulphur atom is bonded directly to the hydrophobic group and so cannot be hydrolysed. All three types are normally used as their sodium salts.

Cationic surfactants are not often used in emulsion polymerisation of acrylic polymers for surface coating applications.

Table 2-1 below lists some surfactant types commonly used in emulsion polymerisation, together with their CMC’s.

TABLE 2-1: TYPICAL SURFACTANTS

![]() Lauryl Sulphate +2EO, Na salt Lauryl Sulphate +4EO, Na salt Sodium Dodecylbenzene sulphonate Sodium Di octyl sulphosuccinate [3] [4]

Lauryl Sulphate +2EO, Na salt Lauryl Sulphate +4EO, Na salt Sodium Dodecylbenzene sulphonate Sodium Di octyl sulphosuccinate [3] [4]

The development of an effective water phase for a polymer latex can take many months of experimentation. The selection can be aided by considering the HLB values for different surfactants. The initials HLB represent the term Hydrophile Lypophile Balance, i. e. the balance between the water seeking (hydrophile) and the oil seeking (lypophile) component of the surfactant. The HLB enables values to be assigned to the material to be emulsified. By blending surfactants with different HLB values a match can be made between the HLB values of the surfactant and the materials to be emulsified. This approach to surfactant selection is not foolproof, but it does enable a selection procedure to be applied to narrow the choice of surfactants likely to be effective in any particular situation. The HLB approach is particularly effective in selecting surfactants to achieve emulsification of an already polymerised material, and is assuming more importance with the move towards low VOC’s and water borne coatings.

Copolymerisable surfactants are available for emulsion polymerisation systems. These are amphoteric molecules containing a reactive double bond. By participating in the polymerisation they improve the resistance of the final coating to water and attack by aqueous solutions.

Classical methods of emulsion polymerisation employ an aqueous phase containing water and surfactant plus initiator to which is added the monomers to be polymerised. Commercial polymerisations utilising acrylic monomers normally use a pre-emulsion technique in which the monomer mixture has been dispersed in the water phase with a surfactant. This pre-emulsion is added continuously during the course of the reaction to the water phase containing further surfactant.

For some acrylic systems the only way to obtain a satisfactory emulsion is by the use of a pre-emulsion technique.

The pre-emulsion must be stable throughout the monomer addition period. The emulsifier system must be compatible with the emulsifiers in the reaction mixture. It is usual to have agitated monomer addition tanks to enable pre-emulsions to be easily formed and to maintain the stability of the emulsion during the addition period.

The pH of the pre-emulsion has a critical influence on the stability, and it is normal to control this between narrow limits to ensure pre-emulsion stability. The precise pH required for stability will depend on the nature of the monomers and surfactant.

13 июля, 2015

13 июля, 2015  Malyar

Malyar  Опубликовано в рубрике

Опубликовано в рубрике