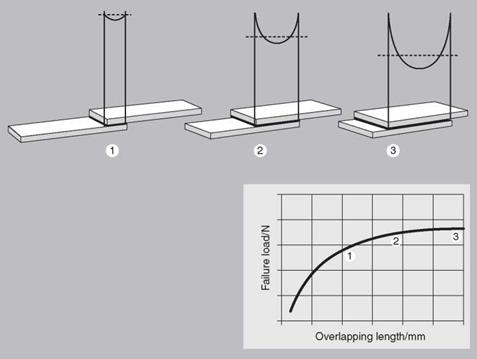

In a standard lap shear joint, if the overlap length is increased, the strength of the joint does not necessarily increase linearly for the same standard conditions (i. e., same adhesive, same substrate, same surface preparation, and so on).

In Figure 5.3 below the bond area has been increased from 1000 mm2 to 2000 mm2 but the strength will only increase by a small percentage. The reason for this can be seen in the stress distribution curves in Figure 5.4.

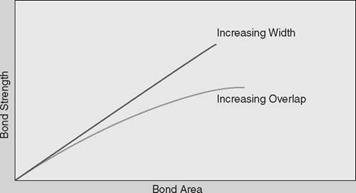

Similarly, in Figure 5.5, both these joints have the same bonded area (1000 mm2) but the joint on the right will be the stronger joint due to the reduced stress concentrations at the end of the joint.

From the shear stress distribution curve in Figure 5.4 we can see that the highest stress is at the ends of the bond and by increasing the joint overlap there is no significant change in the strength of the bond.

40 mm

|

80 mm

25 mm x 80 mm

|

Figure 5.4 The joint strength does not increase linearly with joint overlap due to the stress concentrations at the ends of the joint |

This is because the joint starts to break at the stress peak at the end of the overlap where the adhesion or cohesive strength of the adhesive is exceeded. By increasing the width of the joint, the shear stress distribution is not changed and so the failure load of lap joints increases in the same proportion as the joint width increases (Figure 5.6).

|

Figure 5.6 Increasing joint width will increase the bond strength |

Shear forces can cause mechanical deformations in the substrates and the appearance of peak stress points; this is of particular concern when the components being assembled have a thin cross section and when the materials have a low modulus of elasticity. Failure is most likely to occur at the ends where maximum stress is present.

The ‘nominal shear strength’ of adhesives (as indicated by manufacturers) is measured under controlled experimental conditions. Lower shear strengths must be expected to take into account the specific characteristics of an application. If long-lasting forces of varying nature acting on the bonded joints appear under actual operating conditions, the value used for calculations should be less than the nominal shear strength of the adhesive. When the surfaces of the components being bonded are poorly fitting, the contact between such surfaces must be good and ensured by the assembly technique. When clamping pressure is removed after the adhesive is cured, elastic recovery of the components may introduce pre-service stresses in the assembly; these stresses may be in addition to the forces experienced under operating conditions and should be allowed for.

28 октября, 2015

28 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике