A paint grade of cerium sulfide has also been developed. The pigment has been evaluated in several coatings formulations such as automotive refinish (acrylic-isocyanate binders), general industrial solvent-based systems (polyester-melamine binders), oil-based architectural coatings, and water-based paint. In the latter, performance may be improved by treatment with organics during formulation.

Paint grade cerium sulfide pigment has a very good wet point and flow point because of a significantly low oil demand in comparison with organic pigments. The low oil demand has a positive impact on the viscosity of the mill base; it induces a low energy cost for the milling process and provides a greater flexibility for the formulator by providing the possibility of working at high solids content with low viscosity levels.

In comparison to organic pigments, cerium sulfide formulations have a high “Persoz” level of hardness, coupled with good direct impact resistance. This produces very good gravel impact resistance. Chemical resistance (acid, base and solvent) has been evaluated in paint by the drop test. No specific problem was detected except for organic acids such as acetic acid.

Paint grade cerium sulfide pigments exhibit very good durability in both the xenon test and outdoor exposure. In QUV-A testing, however, the humidity conditions of the experiment are too severe to be representative of outdoor exposure.

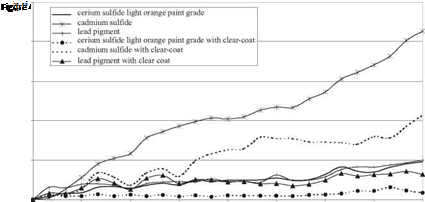

Florida exposure has been evaluated (with a refinish acrylic-isocyanate formulation). Paint grade cerium sulfide outperforms cadmium sulfides, and is equivalent to that of lead pigments (Figure 4.14). In comparison with organic pigments, cerium sulfide paint grade also has a good durability.

|

Cerium sulfides may also be successfully used in powder coatings, thanks to their good weathering resistance.

|

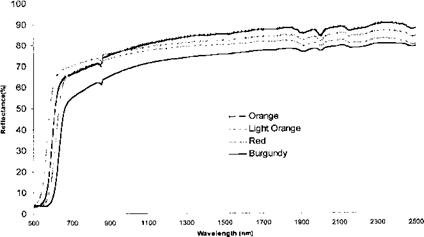

Figure 4.15 Visible and IR Reflectance curves of Light orange, Orange, Red and Burgundy. |

Cerium sulfide pigments are also good candidates for automotive paints, due to the IR reflectance properties of Cerium compounds (Figure 4.15).

1 сентября, 2015

1 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике