As exposed above, three experimental campaigns were performed, involving HJs and SFJs. Referring to the three campaigns the results are presented in the three sub Sections below. When dealing with HJs, the estimation of the coefficient of friction in dry press-fitted conditions is also reported. A comparison between the results of the three campaigns is reported in the Discussion section.

HJs: First Campaign with Higher Interference

In order to estimate the adhesive strength, it was firstly necessary to estimate the coefficient of friction pA. The question was tackled by following the procedure in Section 2, involving 5 samples with different ERs. The results are reported in Table 1: they can be summarized pointing out that the averaged value for jxA is 0.22 with a standard deviation of 0.07. After the calculation of the coefficient of friction, the coupling pressure pC and Fint were estimated for each specimen. Following the procedure reported in Section 2, the amount of force that can be attributed to the adhesive, Fad, and its strength, rad, were computed. Finally, the coefficient Kj, obtained by the ratio Ftot/Fcouph was estimated. All the results, in particular the values of rad and Kj, are shown in Table 2.

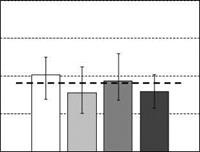

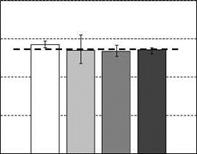

The results, for Tad and Kj, are compared in histograms in Figure 3, with indication of the related ranges of variation. Considering all the tests on shaft — hub pairs (independently of the ER), the shear strength has a mean value of 17.6MPa and an overall standard deviation of 4.38MPa, while Kj is on the average around 1.09: these levels are also reported with a dashed line in Figure 3.

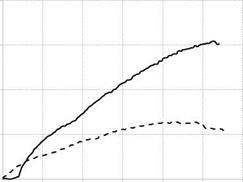

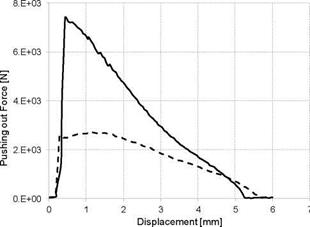

The trends of the coupling forces for PFJs and HJs are compared in Figure 4. The two curves were determined by testing specimens with the same ER=0.4. The trends of release loads, obtained when decoupling the same specimens, are sketched in Figure 5. Plotting the pushing in and pushing out curves for all the tested specimens made it possible to determine the peak values, both for Fcoupi and for Ftot, later used for data processing.

|

Table 1. Summary of the results for PFJs, determination of the friction coefficient (first campaign)

|

|

Table 2. Summary of the results for HJs with ER=0.4; 0.8; 1.3; 1.7 (first campaign)

|

![]()

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

![]()

|

|

|

20 октября, 2015

20 октября, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике