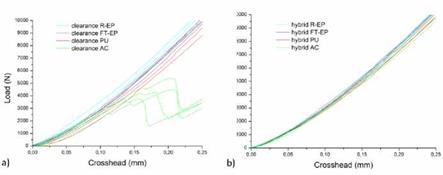

The presence of the interference could also affect the stiffness of the hybrid system. The first elastic stretch of the curves of the hybrid joints were compared with the ones of the systems bonded with clearance, considering all the different adhesives tested. The results are reported in figure 8 (Gallio et al., 2013).

|

Figure 8. First elastic stretch of: a) the samples bonded with clearance; b) the interference-fitted-adhesive bonded samples (with permission of Gallio et al., 2013). |

The differences in the slopes of the curves recorded by testing the bonded samples with clearance were moderated in the hybrid systems by the interference. Thus, it seemed that the interference could be able to control the stiffness of the assembly.

In clearance conditions, among the examined adhesives, the R-EP provided the stiffest samples, while the more flexible PU adhesive provided the samples with the lowest stiffness. The FT-EP samples were characterized by intermediate values. Unfortunately, no precise and comparable information about the Young Modulus of the employed adhesives can be found in their data-sheets. Among the two component adhesives we can say that the epoxy R-EP is a rigid adhesive with a Young Modulus of 6700 N/mm2 and an elongation at break of 0,8 %. The FT-EP is a more flexible and toughened blend characterized by a high peel resistance of 92 N/cm, but no comparable data are available. Finally, the PU adhesive is characterized by a lower Modulus (576 N/mm2) and a higher elongation at break (39 %).

17 сентября, 2015

17 сентября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике