The next case study illustrates that segmentation into blade pockets is indeed very useful. Had it been used in the following case, the consequences of the failure might

|

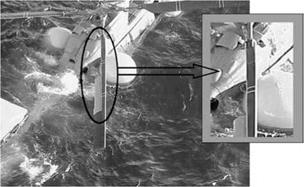

Figure 7.63 Failure: total break-off of a rotor blade. |

have been far less significant. During a flight over sea, severe damage occurred to the main rotor of a helicopter and an emergency landing on water was necessary; unfortunately, the helicopter could not be recovered (Figure 7.63). As the damaged rotor blade was not recovered, failure analysis had therefore to be performed by examining similar rotor blades with comparable flight histories. A photograph taken before the helicopter sank (Figure 7.64) showed a total loss of the rotor blade profile, at the root of the rotor blade, extending to one-third of the blade length, as well as a delamination of the upper outer cover sheet over another third of the length.

The failure pattern suggested that failure was initiated near the root of the blade and resulted in complete separation of the profile over the first third of the blade, subsequently followed by delamination of the upper skin over the central third. The exposure of the spar bond on the upper side of the spar was due to peel loading during separation of the upper cover sheet. Peel loading occurred when the profile was torn off upwards by lifting forces caused by the failure of the bond on the bottom side of the blade in the area ofthe root ofthe blade. The honeycomb core in the final third of

|

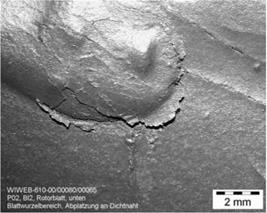

Figure 7.64 Cracks with capillary effects inducing accelerated aging of bond-lines in the rotor blade. |

the length in the center remained intact, indicating that the profile still had sufficient stability under service conditions in the case of an intact outer cover sheet on the bottom side of the blade.

Destructive characterization of the same type of rotor blade revealed the incidence of cracks in the outer skins and along an elastic sealing compound material at the transition between the root of the blade and the pocket profile. Samples from these rotor blades were exposed to outdoor weathering tests and strength tests. It was shown that a failure of the bond is possible when there are cracks along the spar — pocket bond, and when seawater can penetrate via capillary cracks close to the bondline, thereby generating extreme aging conditions that are not covered by all normal tests. Hence, during routine inspections of the rotor blades the quality of the sealants must be checked thoroughly.

7.8.3

1 ноября, 2015

1 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике