Ultrasound burst phase thermography is a new nondestructive defect-selective technique originating from ultrasonic lockin thermography. It provides thermal wave images of defects by ultrasonic stimulation.

In contrast to the sinusoidal-modulated excitation used by lockin thermography, conventional pulse thermography is based upon short optical or acoustical excitation

|

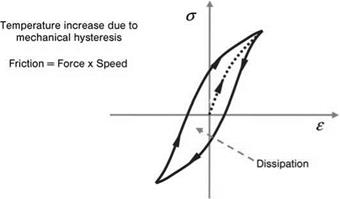

Figure 7.23 The transformation of vibration energy into heat by hysteresis [8]. |

pulses, allowing the measuring period to be significantly reduced compared to the lockin method. However, the thermography images obtained are impaired by the inhomogeneities of the sample surface and the temperature gradients. One way of overcoming this problem is to sue ultrasound burst phase thermography, which combines the advantages of both methods. The sample is excited by short ultrasound bursts, and the temperature modulation is recorded with a thermography camera and the data Fourier-transformed. As with lockin thermography, phase images can be obtained using this method. Compared to the monofrequent sinusoidal excitation, the response spectrum is larger — that is, several modulation spectra can be interpreted with one single measurement [8].

Ultrasound burst phase thermography allows conclusions to be drawn from the phase image directly to the depth position of the defect because the cooling behavior — and thus the range of the thermal wave — depends on the modulation frequency. High

|

Figure 7.24 Laboratory equipment for ultrasonic lockin thermography at the Institute ofJoining and Welding Technique, Technical University of Braunschweig (Germany). |

frequencies display the near-surface area, while low frequencies with a higher range supply information about defects within the component. For interpretation, it is therefore recommended to relate the temperature sequence recorded to the frequencies used to determine the depth position of a defect.

27 октября, 2015

27 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике