7.3.1

Long-Term Static Tests (e. g. Creep Experiments Under Dead Load)

Long-term life prediction for adhesives based on laboratory tests requiring only days, weeks or months remains a demanding challenge. Testing is carried out with the intention of simulating and often accelerating the time-dependent aging effects that may happen to a joint during its lifetime. Due to the specific polymer network structure of most adhesives, their viscoelastic-plastic deformation behavior is strongly time — and temperature-dependent. For long periods of static loading the creep properties of adhesives are dominated by viscous flow. Adhesive creep can be investigated in tensile mode with a polymer bulk specimen (e. g. according to ISO 527-2) or in shear mode with, for example, single lap shear joints according to ISO 11003-2.

Various tests and standards, such as ASTM D2294-96, ASTM D1780-99, ISO 15109 or EN 1943, have been developed to evaluate the creep resistance of adhesives, by monitoring the time — and load-dependent displacement of an adhesive specimen under shear load, or by recording the time to failure.

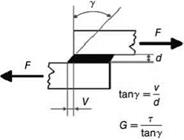

In the engineering process ofbonded structures the limits for maximum tolerable deformations in the structure to maintain functionality and appearance are important for the design of the adhesive joint. The shear strain of adhesive joints is generally expressed as tan g = s/d, where s is the displacement of the adherents and d is the thickness of the adhesive layer (Figure 7.13).

In static load creep experiments, a dead load is applied to the adhesive joint and the initial displacement, as well as the increase in strain over time during the test, are recorded. Standard creep experiments provide basic results for the assessment of time-dependent deformation of adhesives with high plasticity.

Another common experimental procedure is the relaxation test. While creep experiments apply a constant load to the sample and follow the increase of strain over time, the relaxation technique applies a fixed strain to the specimen at the start of the test and then records the decrease in stress over time caused by plastic deformation of the adhesive polymer. The difference in creep testing versus relaxation testing is illustrated in Figure 7.14.

|

Figure 7.13 Deformation of an adhesive joint under shear stress. |

7.3.2

18 октября, 2015

18 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике