7.2.1

Tensile Stress (e. g. Butt Joints)

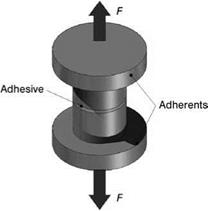

A tensile test ofan adhesivebond puts the adhesive in a state ofstress inwhich the bondline is perpendicular to the direction of the force applied to the specimen. A typical sample for evaluating the tensile properties of an adhesive is shown in Figure 7.2.

|

Figure 7.2 The basic geometry of tensile tests. |

This specimen is similar to that used in ASTM Test Method D2095. Metal rods are generated according to the exacting specifications described in ASTM Standard Practice D2094. The ends of the metal rods must be machined so that the surfaces contain no burrs that might cross the adhesive gap, and that a parallel adjustment of the adherents is guaranteed during assembly. Any angular misalignment of the surfaces could force the test to be one of cleavage rather than tension. The metal rods are butted up to an adhesive which joins them — hence the term ‘butt tensile’ test. When the adhesive has cured or set, the specimen is loaded in tension up to failure of the joint, as depicted in Figure 7.2. Both, the tensile stress at break and the mode of failure are reported. The major drawback of this type of test is that, although an average stress at failure is reported, the actual stress distribution in the bond-line is not uniform throughout the adhesive, with higher stresses occurring at the center of the butt tensile specimen compared to the edges. In fact, the average stress at failure is more likely due to these edge effects rather than to the actual tensile strength of the adhesive. Butt tensile tests are rarely used to evaluate adhesives because the mode of loading is typically not used in adhesively bonded structures. Therefore, tension tests provide reasonably accurate information with regard to the tensile strength of adhesives. Tensile strength data may be suitable for specification acceptance, service evaluation, manufacturing control, and research and development purposes. However, tension tests are not considered significant for applications differing from the test in rate, direction and type of loading [1].

A test method similar to D2095 is described in ASTM D897 in which studs are glued together and pulled apart in tensile mode. This ‘stud pull-off test’, which is an interesting variation on the tensile test, involves a metal stud being adhered to a surface by means of a structural adhesive. The stud is machined in such a way that an actuator can be attached to its back, allowing a tensile force to be applied between the stud and the sample surface. This test can be used to determine a practical adhesion value to a particular surface. The method can also be modified so that the stud is bonded to a coated surface. Then, if adhesion between the adhesive used to bond the

|

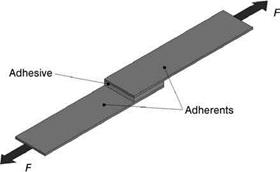

Figure 7.3 The basic geometry of a lap shear specimen. |

stud and the coating is good, a ‘figure of merit’ can be obtained for the adhesion of the coating to the surface.

7.2.2

15 октября, 2015

15 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике