PSAs require a characteristic combination of rheological properties; first, they must wet the adherent surfaces rapidly and completely to build up a good holding force. The quality of the wetting is determined not only by the viscoelastic behavior of the PSA but also by the surface tensions of the adhesive and the adherents.

During bonding, a PSA is required to have adequate flowability to adapt to the surface structure of the adherents. The building up of adhesion may take place slowly, usually on the order of a second or more, so that the adhesive has enough time to deform. Mechanical strains created by compression must be relieved by relaxation within the adhesive in order to prevent detachment ofthe adhesive from the adherent surface. The finished bond must also resist the peeling and shearing forces that occur during service.

Build-up of the bond takes place at a low deformation rate, while destruction of the bond is a relatively rapid procedure, for example when the adhesive is removed. The time given to the adhesive to yield is on the order of one-tenth of a second. Considerably higher deformation speeds may occur in peel tests. In shear tests, the properties of the adhesive are determined by its creeping behavior at a relatively low load during a long period of time. Only PSAs make it possible to combine these mutually exclusive properties owing to their complex viscoelastic behavior.

The correct synthesis or formulation allows the physical properties to be fine-tuned in order to obtain a balanced combination of tack, peel resistance and inherent strength (cohesion).

Properties of Pressure-Sensitive Adhesives as a Function of Temperature

Dynamic mechanical analysis (DMA) makes it possible to examine the viscoelastic behavior of PSAs over a wide range of temperatures, and to determine the reversible (elastic) and irreversible (viscous) reaction of a polymer to deformation as a function of the temperature or rate of deformation [6]. Sinusoidal mechanical oscillation is applied to an adhesive sample, after which the elastic and viscous component of the modulus may be determined from the amplitude and phase shift of the stress-strain curve (see Section 7.2.2).

The viscoelastic properties of a PSA are characterized by the storage modulus G’ (elastic modulus) and the loss modulus G" (viscous modulus). The phase angle tan 8 is the ratio of G» and G’, and describes the energy loss in relation to the energy storage per cycle. Over a specified temperature range, the peak tan 8 is an indicator of the dynamic Tg of the adhesive tested.

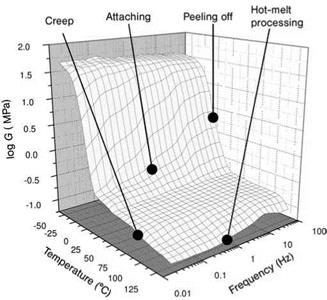

The DMA spectra of PSAs, plotted as a function of the excitation frequencies tested, allow the viscoelastic behavior of the adhesives to be determined in the relevant ranges of temperature and deformation rate, respectively. Figure 5.6 demonstrates the storage modulus (G’) of a PSA at the relevant frequencies with view to application, peeling, creeping and hot-melt processing. DMA is most useful for both the developers and customers of PSAs.

|

Figure 5.6 The dynamic mechanical analysis (DMA) spectrum of a pressure-sensitive adhesive (PSA). |

5.1.5 Tack

Tack is the property of a PSA that enables it to form a bond immediately after the adherent and adhesive are brought into contact; a strong force is then needed to separate the joint. A PSA must be removed cleanly from the surface without leaving a residue. When building up the bond, a PSA is expected to have a very good deform — ability and to act as a liquid. When the bond is separated, it is expected to have a high modulus and to act as a solid. A modulus of 0.1 to 1 MPa is required for a PSA to have proper tack during the time period of 1 to 100 s which is the decisive relaxation time period during the build-up of the bond. This requirement for tack is termed the ‘Dahlquist criterion for tack’, after the scientist who first studied this phenomenon [7].

5.1.6

30 августа, 2015

30 августа, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике