Numerous theories have been proposed for a long time, and referred to in even the most recent literature, to explain observed phenomena of adhesion. In the following

|

Adhesion |

Thermodynamical |

Adhesion |

|||

|

by physical |

interpretation of |

by chemical |

|||

|

interactions |

adhesion |

bonds |

|

Polarization |

Electro- |

Oiffusion |

Thermodynamic |

Chemisorption |

|

theory after |

statical |

theory |

theory after |

theory after |

|

0Є Bruyne |

theory after |

after |

Zisman, Fowkes, |

Brock man n |

|

(1935) |

Derjagin |

VojUtSkii |

Good and Wu |

(1969) |

|

(1950) |

(1960) |

(1963) |

|

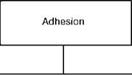

Figure 3.2 Classical adhesion theories. |

|

|

sections these theories will be briefly assessed, taking into account that each of them only partly explains the true behavior of adhesive bonds. The most important adhesion models are summarized in Figure 3.2. Although, for the sake of completeness, the theory of‘mechanical interlocking’ has also been included here, it will not be discussed further because it is quite insignificant for bonding technology today. In contrast, the concept of ‘specific adhesion’ will be presented in detail, summarizing all other adhesive phenomena based on physical and chemical interactions.

At the time when natural science first began to analyze the phenomenon of adherence, no generally valid knowledge was available regarding the physical and chemical interactions which take place between matter particles. The only possible approach was to calculate the energy balance of the process taking place when a solid — state material was wetted by a liquid, assuming that the wetting characteristics — which could be measured macroscopically — were ideal. This thermodynamic approach is based on the fact that, in terms of physics, the surface tension of liquids and solid objects is a type of energy; that is, work is done in order to create the surface of a material. Consequently, techniques to measure this energy were developed first for liquids, and then adapted for use with solid-state materials.

The calculation of adhesion was based on the contact angle (a; see above) which is formed when a drop of a low-viscosity liquid is applied to a solid-state material. Young’s equations of wetting [1] can be calculated by using the surface tensions of the materials when this system, surrounded by its ambient gas saturated with the vapor of the liquid, is in a state of equilibrium (i. e. at rest). As surface tension is a quantity of energy, the Dupre equation [2] makes it possible to calculate the work of adhesion liberated when a liquid wets a solid-state material. The concept of solid surface free energy was later introduced into the Dupre equation to make it more accurate [3]. Subsequently, Wenzel [4] took into consideration that the shape of the solid surface also influences the contact angle, by introducing a factor of roughness into the equation. Wenzel’s roughness factor is defined as the ratio of the true area of a surface (actually present on the microstructure of a surface) to the geometrically projected area.

The aim of these calculations was to deduce the strength of adhesive assemblies from the work of adhesion. This is possible as long as there is no mixing of the substances during the wetting process — that is, there are no penetration or chemical interactions that would resulting in a reversibility of the wetting process. In this case, the work necessary to separate the two materials after wetting is equal to that liberated during the wetting process. If such work is simply assumed to be constant over a defined range, it can be converted into strengths that are quite similar to those that can be determined with modern-day measurement techniques. In reality, however, the energy balances involved in the creation and restitution of surfaces or interfaces cannot be applied, even if the interfacial tensions are subdivided into their dispersion force components and their polar force components. In terms of thermodynamics, the wetting process virtually cannot be assumed to be reversible: it can be shown by measurement techniques that the original surfaces characterized by defined surface tensions will not be restored when the surfaces are separated from each other. If, for example, a drop of epoxy resin is cured on polyethylene, its surface tension is approximately 35 mN m-1 on the side that faces the air. However, when the drop is lifted from the polyethylene surface, its surface tension will be similar to that of the polyethylene surface because, despite poor wetting, some slack polyethylene molecules from the solid surface are most likely sticking to the drop material at the moment it is stripped from the surface.

Furthermore, when explaining adhesion by means of the concept of interfacial energies, surface tensions are rather assumed to be material constants. It is assumed that, after separation of the surfaces, the surface tensions of the liquid and the solid material, respectively, are still the same as before wetting. However, present knowledge indicates that, for various groups of materials, this assumption does not correspond to reality, even if there are no components of one material sticking to the other. Polymers in particular have a distinct ability of restructurization, as has been demonstrated in various recent studies [5]. Restructurization means that polymers are capable of adapting their surface condition — and hence their surface energy — more or less rapidly to the ambient conditions that surround them, even in the solid state. Moreover, the surface of each material — no matter how it is defined — depends on how it came into being. Therefore, it is not logical to proceed on the

assumption that materials have constant surface properties, including the assumption of a defined surface energy.

This may be easily demonstrated with the following model. Let us suppose that a conical container is filled with molten polyethylene. When, after cooling, the polyethylene cone is removed from the container the solid material will present two different surfaces: (i) the surface that was formed on the side facing the container; and (ii) the surface that freely solidified in the air. A third, imaginary surface can be produced by cutting the cone into pieces with a knife. On those surfaces which formerly faced the container the polyethylene chains will be arranged in the form of loops, following the contours of the container. But, on the surface exposed to the air, they virtually will not present any roughness at all; they may even have slightly begun to oxidize due to the presence of oxygen in the air — a process that takes place more rapidly in the molten state owing to an improved input of energy. On the surface cut with the knife, however, the molecules could not arrange; they were separated in the solidified state, and those molecules hit by the knife were shortly transformed into radicals before being saturated by reactions taking place between them and residues of the knife or the air, resulting in the creation of stable systems.

Consequently, the polyethylene pieces produced have at least three different surface tensions. If this experiment is performed using containers of the same form, but made from different materials (e. g. Teflon® or silver), the polyethylene side that faced the wall of the container will again have different surface tensions depending on the container material used. In the case of a silver container, the polar polyethylene groups (created in the melting process) will probably have arranged towards the container, whereas in the case of Teflon®, they will have arranged towards the material interior.

To sum up, the simple thermodynamic approach is based on the postulation that adhesion is a two-body problem where the involved partners do not influence each other. But this has been shown not to correspond to reality.

By no means can the measurement of interfacial energies be used to explain adhesion. However, some important surface tension quantities that can easily be measured, may indeed rapidly provide some first indications of how adhesion will take place, or which problems may prevent adhesion from being built up.

3.2.1

18 августа, 2015

18 августа, 2015  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике