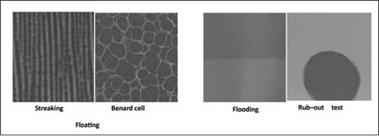

Flooding and floating (Figure 5.4) is a defect that occurs in paint systems containing a combination of pigments that differ significantly in their wetting characteristics and particle sizes. It occurs after application in the wet film and is caused by segregation of the different types of pigments. This segregation is strongly influenced by flocculation of similar pigment particles. When this non-uniform pigment distribution is vertical, it is termed floating, which appears in the form of Benard cells or streaks; on other hand, horizontal separation is termed flooding, which appears as a uniform change in color of the film while it is wet and can only be evidenced by a rub-out test. In this test, after a short drying period, part of the wet paint film is rubbed with the finger until almost dry; a color difference between the rubbed section and the rest of the film indicates flooding. The separation is caused due to differential mobility of different types of pigment particles under the influence of local eddies in the drying film. Flooding and floating can be avoided either by controlled flocculation of various pigments using an additive, or by using polymeric dispersants. Once different pigment particles are associated with each other by controlled flocculation, they no longer have a chance of segregation. Polymeric dispersants control flooding and floating by influencing pigment mobility through a

|

|

strong interaction between an adsorbed dispersant molecule and surrounding resin molecules, as opposed to flocculation, and therefore is the preferred route for high-gloss top coats.

21 декабря, 2015

21 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике