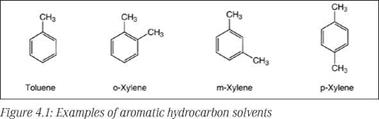

Compared to aliphatic solvents, aromatic hydrocarbons (Figure 4.1) have higher solvency for almost all types of resins. Aromatic hydrocarbons are also used as diluents for coatings based on nitrocellulose, cellulose esters, and ethers in combination with active solvents, such as esters and ketones. Aromatic solvents that are commonly used in the coating industry are toluene, mixed xylene (xylol) and two types of high-flash aromatic naphthas. Aromatic naphthas are primarily higher-substituted alkylbenzenes, including tri — and tetramethylbenzene, isopropylbenzene (cumene), methylethylben — zene and diethylbenzene. There are two grades of aromatic naphthas, one with a flash point higher than 38 °C and predominantly C9 aromatics, and another with a flash point higher than 60 °C and

|

|

C10 aromatics. Styrene and vinyl toluene are also aromatic hydrocarbons that act simultaneously as solvents and reactive diluents for chemical crosslinking with unsaturated polyester resins and in UV-cured coatings.

11 декабря, 2015

11 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике