Fine particles of malleable metals in elemental form are also used as pigments in coatings for aesthetic as well as protective purposes. They are generally platelet-shaped particles, but some are spherical.

Pigment Metal 1; formula: Al

Aluminum pigments are the most often used metallic pigment in surface coatings. They are prepared from high purity aluminum metal by ball milling fine aluminum powder in the presence of a hydrocarbon solvent and grinding aids such as stearic acid and then formed into platelet-shaped particles. They are normally supplied as pastes in hydrocarbon solvents and occasionally in powder form.

There are two main types of aluminum pigments commercially available:

• Leafing type

• Non-leafing type

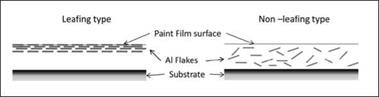

These types primarily differ in their optical effects due to different orientations in coating films. Their orientation is mainly controlled by adsorption of surface-active agents (typically stearic or oleic acids) on the surface of the platelets.

Due to the adsorbed layer of stearic acid, leafing type aluminum platelets float on the surface of the paint film and align themselves parallel to the surface during the paint’s drying process. This gives the appearance of a mirror-like continuous film of metal. As the film dries, it forms overlapping layers of aluminum platelets that provide an excellent aesthetic effect and an effective barrier to moisture and corrosive species as well as reflection of heat and UV light.

On the other hand, non-leafing type aluminum pigments, which are generally stabilized by oleic acid, are wetted well by binder due to their non-polar surface, and hence they do not float on paint film, but rather get distributed more evenly in the film. Dried films appear as though tiny mirrors are embedded at different angular orientations, resulting in a sparkling visual effect. These pigments are used to produce a desirable aesthetic metallic effect in automotive coatings and printing inks. The orientation of leafing and non-leafing type aluminum pigments in paint film is illustrated in Figure 3.6.

These pigments are available in a wide range of particle sizes and aspect ratios to produce different aesthetic effects. Aluminum pig-

|

Figure 3.6: Schematic representation of orientation of leafing and nonleafing aluminum particles in paint film |

ments are sensitive to acids and moisture, which results in de- leafing, loss of sheen and hydrogen gas evolution.

15 ноября, 2015

15 ноября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике