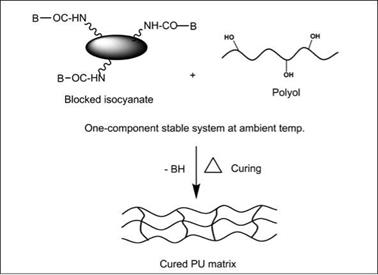

Blocked isocyanates are a type of urethane that are made from reaction of polyisocyanates with special active H-compounds that form thermally reversible urethane linkages. When heated above a certain characteristic temperature, called the deblocking temperature, blocked isocyanates undergo a reversible reaction with formation of free — NCO groups and an active H-compound. Some examples of such active H-compounds, known as blocking agents, and their deblocking temperatures are: caprolactam (~170 °C), methyl ethyl ketoxime (~150 °C) and 3,5-dimethylpyrazole (~ 125 °C). Blocked isocyanates prepared from a wide range of polyisocyanates and blocking agents, with a range of deblocking temperatures, are commercially available. Thermally curable one — component polyurethane coatings can be prepared by combining blocked isocyanates and polyols (along with other paint ingredients), and after application, require thermal curing above the deblocking temperature of the blocked isocyanate. Figure 2.65 depicts the composition and curing of a one-component blocked isocyanate system. During curing, free isocyanate groups are generated and

|

Figure 2.65: Schematic representation of one-component blocked isocyanate system |

react with polyols to form a cross-linked urethane matrix. Due to the absence of free — NCO in the can, such systems have longer shelf-life, and do not require especially moisture-free pigments or solvents.

20 октября, 2015

20 октября, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике