Transparent yellow iron oxide is manufactured by precipitation ofiron(II) hydroxide or carbonate fromaverydilute iron(II) salt solution and subsequentoxidation, e. g. with air, to FeOOH. The quality is determined by parameters such as the concentration of the iron(II) salt during precipitation, precipitation temperature, oxidation time,

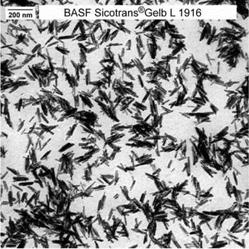

pH and maturing time of the precipitated pigment particles in the suspension. The pigment is washed by decanting, filtered, dried and ground. The particles are needleshaped with a length of 50 to 150 nm, width of 10 to 20 nm and thickness of 2 to 5 nm, depending on the product (Figure 5.39) [5.188].

Fig. 5.39 Yellow iron oxide, transparent (precipitation process) [5.186].

Fig. 5.39 Yellow iron oxide, transparent (precipitation process) [5.186].

Transparent red iron oxide is manufactured by thermal decomposition of yellow iron oxide and elimination of water at temperatures of300 to 500 °C. It is best to start from the dried, crushed filter cake. The pigment is subsequently ground. Pigments with particularly low conductivity values are obtained by additional treatment [5.186].

It is also possible to obtain transparent red iron oxide with a hematite content of 85% directly by precipitation of iron(II) hydroxide or carbonate from iron(II) salt solution and oxidation with air at ca. 30 C in the presence ofone ofthe chlorides of magnesium, calcium or aluminum [5.189].

Semitransparent iron oxide pigments of extreme chemical purity are obtained by direct combustion of iron pentacarbonyl in an excess of air at 580-800 °C to form iron oxide and carbon dioxide (Figure 5.40). The resulting pigments range from orange to red in color. The pigment particles are 10 to 20 nm in size, X-ray amorphous and isometricin shape [5.190, 5.191]. Comparedwithtransparentredironoxides fromthe precipitation process, pigments produced by the carbonyl process are relatively easy to disperse, but the larger particle size also means they are not so highly transparent.

A comparison of transparent iron oxide pigments formed by the precipitation and the combustion process is shown in Figure 5.41.

5.4.1.2

15 января, 2016

15 января, 2016  Pokraskin

Pokraskin  Опубликовано в рубрике

Опубликовано в рубрике