This is the name given to the composite bridge deck slabs developed by the Wolfson Bridge Research Unit at Dundee University (1-3). The concept was developed with the object of developing a bridge deck with a weight saving over the conventional alternatives. Because a large part of the cost of medium and long span bridges is devoted to supporting the weight of the roadway deck, a lighter deck should reduce the cost of the supporting structure. A lightweight precast decking element system was therefore developed to span between the top flanges of longitudinal stringers and cross-beams. In principle, the concept may be likened to a more efficient form of the dished steel buckle-plates supporting a mass concrete base for roadway surfacing, a form of roadway deck that was employed on many steel bridges built between 1890 and 1935.

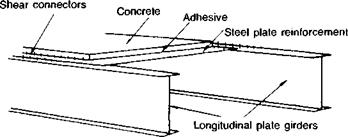

The materials chosen to comprise the skin and core were steel and concrete, respectively. A top plate or skin was found to be more or less redundant in quasi-static bending and shear, giving rise to the term ‘open sandwich’. The concept based upon a flat soffit plate is illustrated schematically in Fig. 8.1. The combined thickness of steel and concrete is of the order of 150 mm, and the resulting precast unit is about 30% lighter in weight than a conventionally reinforced concrete slab of similar strength because (a) there is no concrete cover below the plate, and (b) the plate carries biaxial stress which, together with a reduction in dead weight from the lack

|

Fig. 8.1. Open sandwich construction. 268 |

of cover, enables a reduction to be made in the depth of concrete above the plate. During fabrication the steel plate acts also as the soffit formwork, thereby enhancing any potential economic benefit. In a typical medium-span bridge, the lighter deck can lead to a reduction of 10-15% in the cost of the supporting structure.

These ‘open sandwich’ slabs may be based on either a flat soffit plate or a plate curved slightly upwards to form a shallow arch, or inverted catenary. Their applications extend to repair and maintenance work, as well as in new construction. For instance, interest in this concept has been expressed in America for the replacement of existing highway bridge decks suffering from rebar corrosion. Upgrading through enhanced structural performance may be conferred additionally by the formation of a replacement composite deck with overall continuity. These slabs may also have application as a flooring medium in building structures, perhaps in competition with the use of cast-in-place decks utilising profiled steel sheeting. Alternatively, slabs could be prefabricated using profiled steel plates as the bottom plate or skin, with the adhesive providing the shear key. A number of possibilities exist, including the substitution of the main steel and concrete component materials for alternatives.

8 сентября, 2015

8 сентября, 2015  Malyar

Malyar

Опубликовано в рубрике

Опубликовано в рубрике