Barcode labels, nameplates or warning labels not only communicate important information, but also convey the manufacturer’s image. Therefore, it is of utmost importance that they adhere reliably to the substrates.

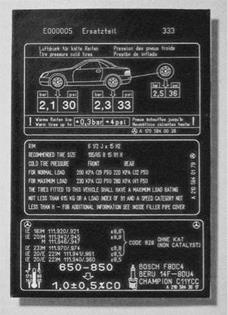

A wide variety of pressure-sensitive films provides for product identification under the most severe conditions. Indeed, every day, label manufacturers are developing new customized identification systems, for example for the automotive (Figure 8.55) or electronics industry, that defy most adverse conditions caused by chemicals, temperatures or difficult surfaces.

Special recyclable labels are available that have been tailored to the recycling needs of popular plastic materials [e. g. PC, ABS, PC-ABS, PS, high-strength polystyrene (HIPS)] used for the manufacture of casings for information and entertainment electronics equipment, avoiding the time-consuming and costly removal of labels before starting the recycling process.

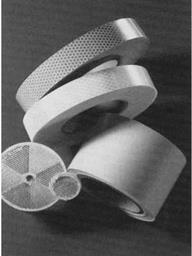

In industry, there is a trend towards ever-increasing rates of turnover with regards to products of all kinds, and this has immediate impact on processes such as sorting and counting, controlling, storing and commissioning. To this end, retro — reflecting materials are available that make it possible to mark products or their transport containers for identification by photoelectrical scanning systems (Figure 8.56). According to the requirements, these materials are attached directly to the product or its transport container in the form of a single sign, or a combination of signs (code).

Laser engraving allows all types of fonts and logos (high-density barcodes included) to be produced by removing the upper layer of a double-layer acrylic film by means of a laser beam, exposing a different colored material layer below as information

|

Figure 8.55 A retroreflecting license plate. |

|

Figure 8.56 Retroreflecting labeling tapes. |

|

Figure 8.57 Information label in cars. |

(Figure 8.57). At the same time, the laser beam can cut any label form, making die-cuts redundant. Laser engraving offers the following benefits:

• noise-reduced, flexible processing

• easy format change

• permanent, nonremovable printing

• no preprinting and precutting required

• suitable for small print runs

• perfectly suited for high-resolution barcodes

These films are employed for labeling purposes in the automotive industry, for transfer-evident labeling, and for high-performance labeling.

The special features of safety labeling films only become evident in the case of a manipulation attempt. Indeed, when trying to remove a label once bonded, all hopes of being able to transfer the label intact are dashed because the label is destroyed. These special films detect whether a manipulation attempt has been made.

20 декабря, 2015

20 декабря, 2015  Pokraskin

Pokraskin

Опубликовано в рубрике

Опубликовано в рубрике